“Right sizing” your product means designing products that fit the market and can be practically produced. Waiting to long to release a product to manufacturing and the market can be worse than releasing too early, because if you wait until its perfect then you’ll never get it out the door. Lets talk about the concept of having just enough features and benefits for your product to succeed. Solve a simple problem in a simple way and you’ll have a great product.

Intern Update – Kitchen Set Prototypes

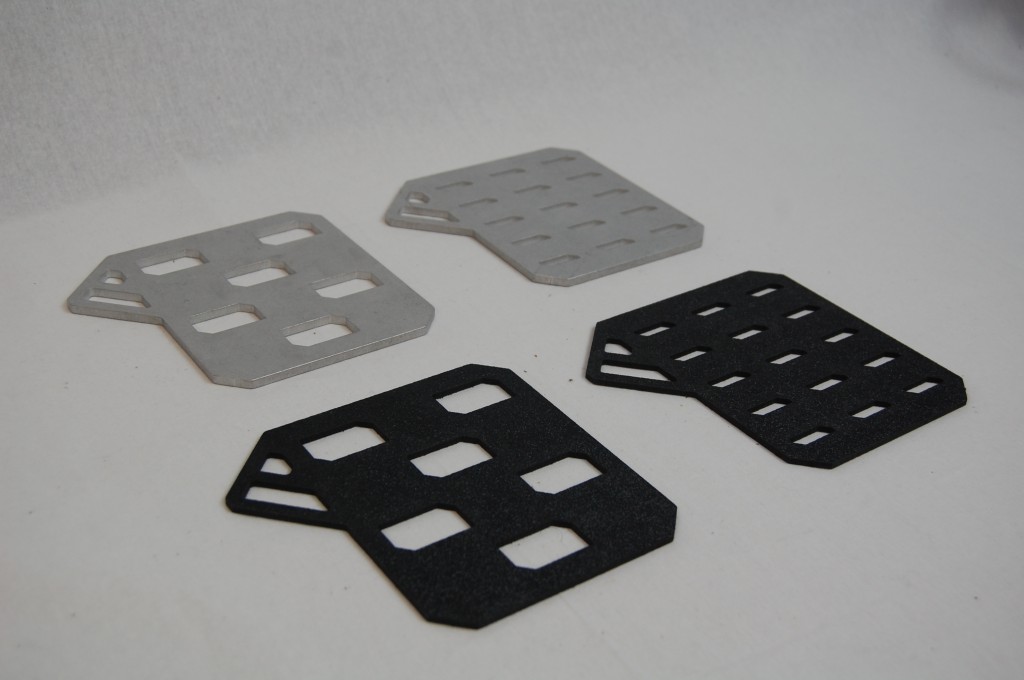

THEY’RE BACK!! Prototypes of the Kitchen Set (Cooking Utensils Rest, Eating Utensils Rest, and Dish Towel Holder) from my last blog are back from the water jet cutting facility.

The prototypes were made using 3/16″ Aluminum and 1/8″ ABS Plastic.

Here is a look at the Cooking Utensils Rest and Eating Utensils Rest in Aluminum and in Plastic:

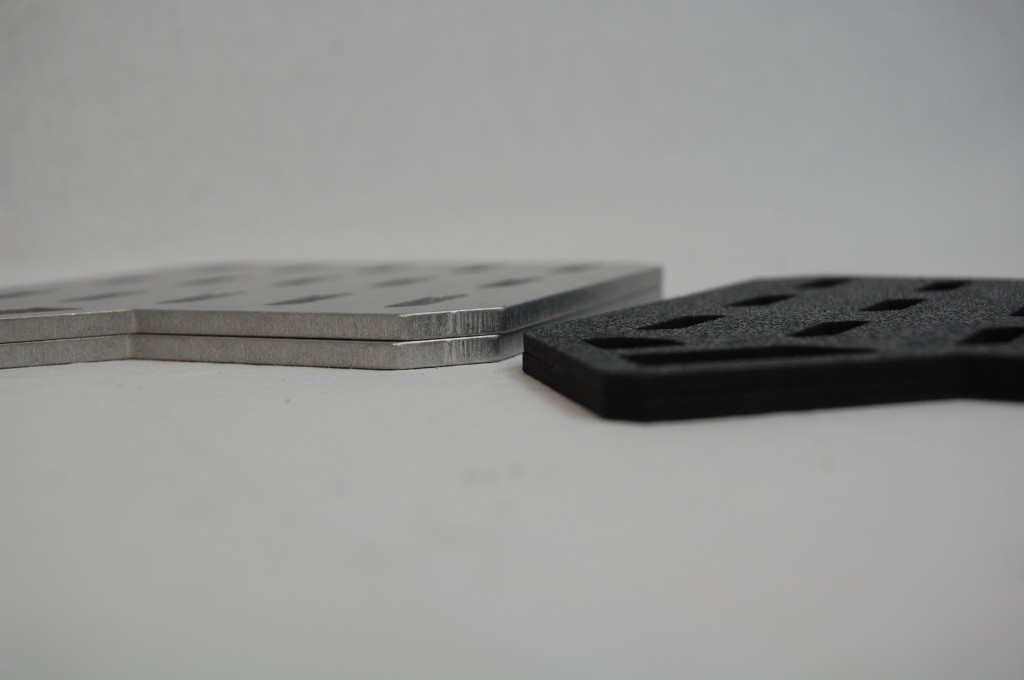

This picture shows the thickness comparison of the two materials:

- 3/16″ Aluminum vs. 1/8″ Black ABS Plastic

- The aluminum Kitchen Rest Set:

- The plastic Kitchen Rest Set:

Let’s put them to use! In this configuration, campers can keep their utensils on the picnic table:

- ALUMINUM Set on the table:

- PLASTIC Set on the table:

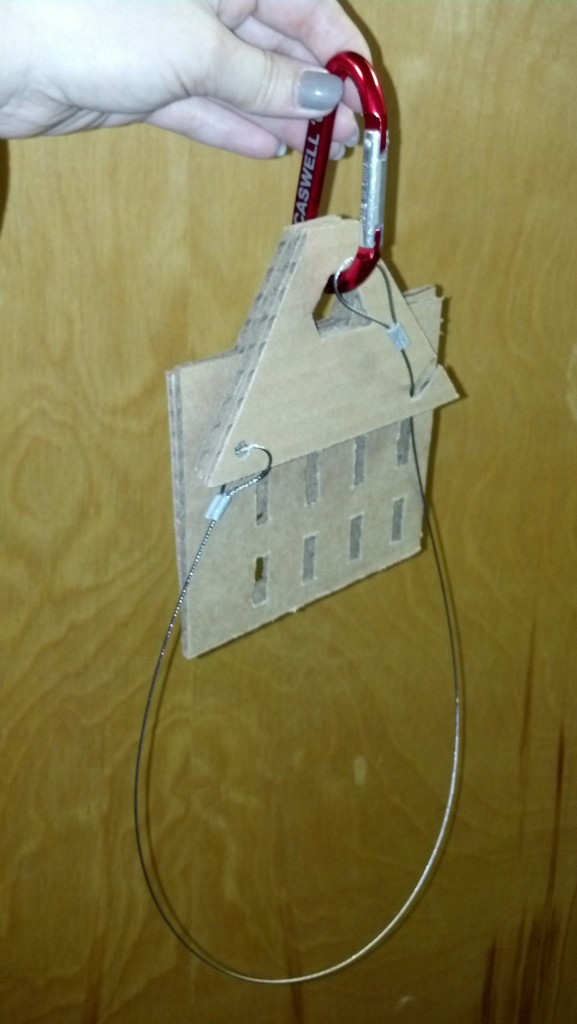

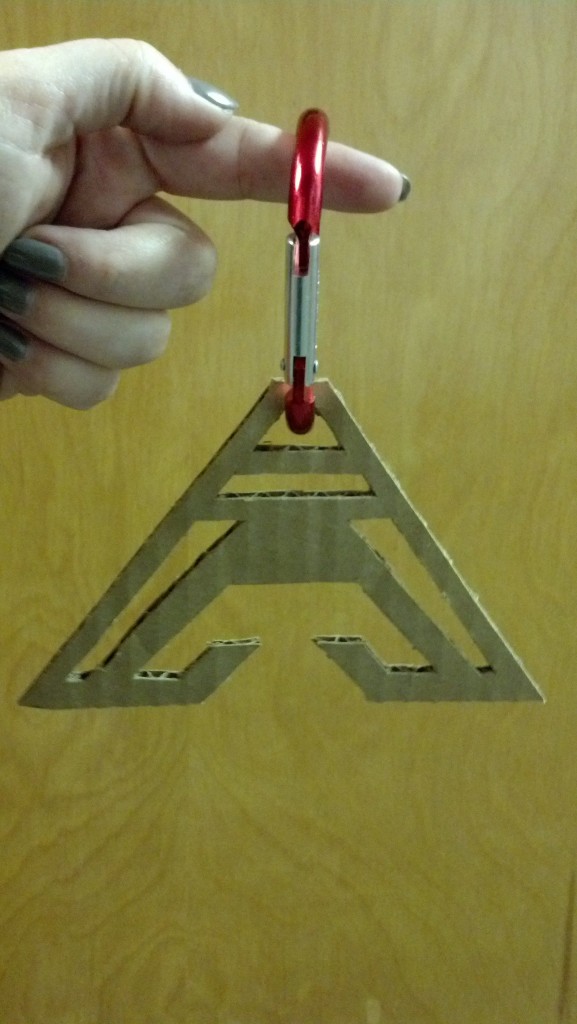

Another option is to hang them from a carabiner:

- Hanging Option

Front View of the Plastic Set, Hanging:

Rear View of the Plastic Set, Hanging:

- Observations of the Utensils Rests:

My observations of the 3/8″ Aluminum Utensils Rests:

Pros: rugged look, feels like a quality product, durable

Cons: rather heavy, limited color options

Recommendations: I would like to see this material in a thinner version.

My observations of the 1/8″ Plastic Utensils Rests:

Pros: lightweight, cheaper production, multiple colors

Cons: thin features (on handle) could break

Recommendations: If this material was used, it would need to be textured on both sides to look and feel like a finished, quality product.

Now let’s take a look at the Dish Towel Holders:

As I wrote in my previous blog, I had designed three different versions of the Dish Towel Holder. We created prototypes of all three versions, and here they are, also in 3/16″ Aluminum and 1/8″ ABS Plastic.

Option A:

Option B:

Option C:

The Dish Towel Holders in Use:

Option A in Plastic and Aluminum:

Option B and C in Aluminum:

Option B and C in Plastic:

- Observations of the Dish Towel Holders:

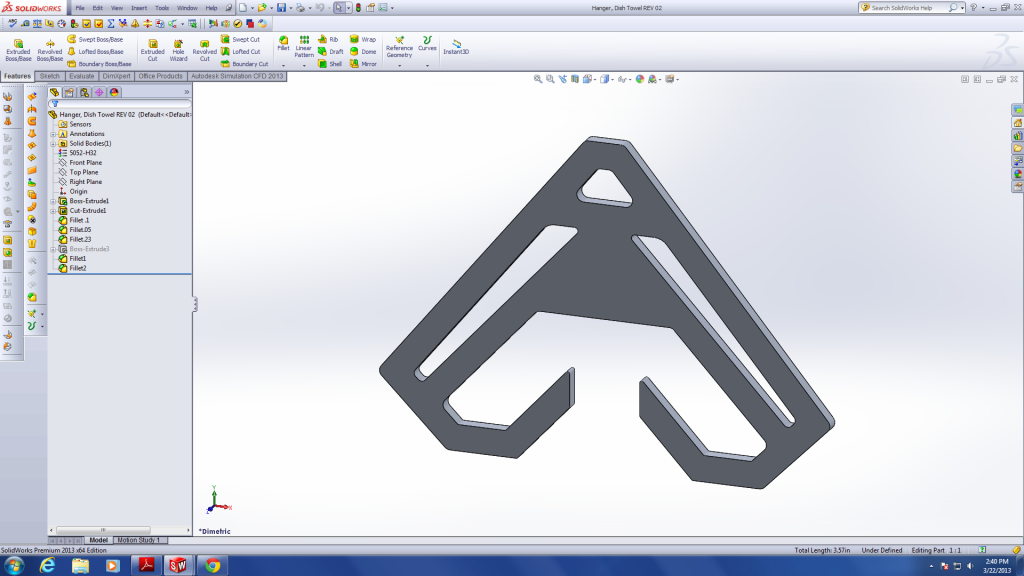

In my personal opinion, Option A is not as aesthetically pleasing as Options B and C. I have decided that Option B and Option C would make a great pair, since they are the same overall shape, but offer slightly different functions. Either of these options could extend well beyond the kitchen aspect of camping by hanging other items that would otherwise be taking up valuable surface space. The teeth on Option B could be used for any fabric item such as a beach towel or wet bathing suits. The hooks on Option C could be used for things such as a flashlight or keys.

Next steps:

I will be visiting the water jet cutting facility to explore some other options for materials and thickness of the materials. I have also decided to decrease the height of the Eating Utensils rest, since there is a lot of extra material in the gaps between the smaller silverware. The Cooking Utensils Rest will stay the same size.

If you have any opinions or questions, feel free to leave me a comment, and thanks for reading!

-Rachael

Podcast: Fuzzy Front End

“Fuzzy Front End” is a funny term and one you rarely hear about outside of product design circles. Let’s take a few minutes and talk about what the term means and how use this stage of the product design process to refine your product vision and gather the data and feedback you need to design a better product.

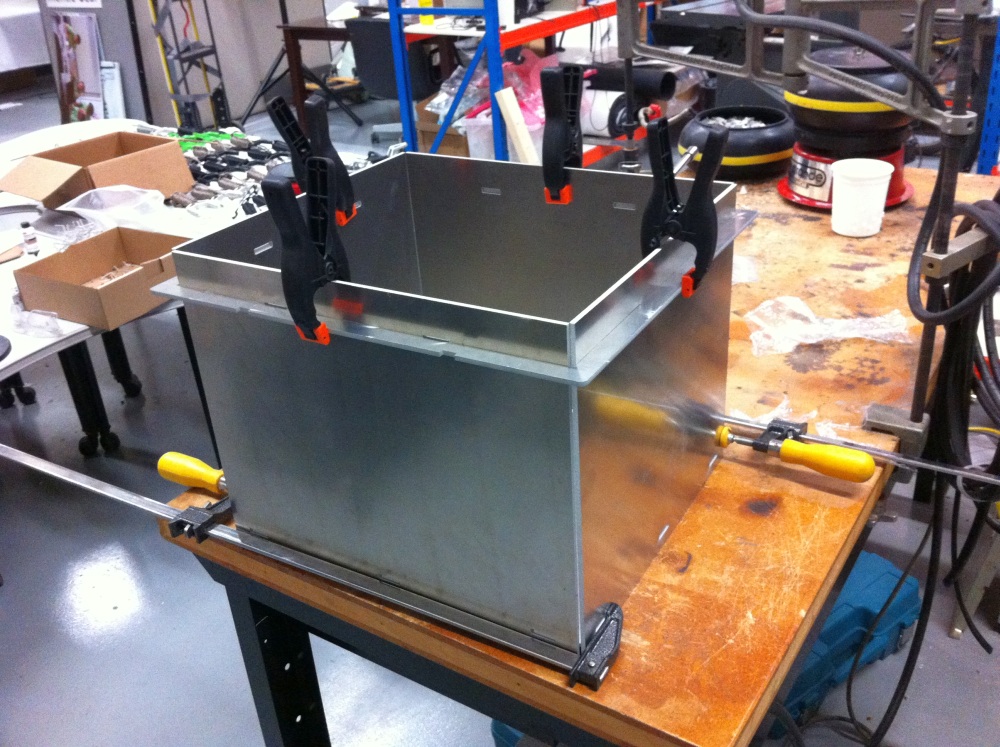

Fun Stuff – EMP Resistant Box

I think its fitting that the parts for the EMP Resistant box came back on the same day as the first night of the new season of Revolution! No irony is lost there. For those of you who don’t follow Revolution, its a TV show about an EMP like device that takes down life in America as we know it.

You can see below where we have assembled the shell for the lower portion of the box.

Then we check to make sure the box is square in the fixture.

As Hannibal (A-Team) said “I love it when a plan comes together”. The fact that just about everything fit together first try without any major “Adjustments” resulted in a lot of smiles.

The next step is to make a small adjustment to a some minor parts on the bottom of the main chassis, deburr the plates, reassemble and carry to the welder.

Have a great day and enjoy Revolution tonight, as you’re wonder if you need an EMP resistant box too. I’m pretty where you can get a really nice one to keep all of your electronics safe.

Have a great evening!

Montie

Intern Update – Rachael Hughes

Hello Montie Design community! I am Rachael Hughes, a design/drafting intern here at Montie Design since January 2013. I am currently a senior at North Carolina State University in Technology, Engineering, and Design Education with a concentration in Graphic Communications.

My most recent project at Montie Design grew from a challenge from Montie to design a product for family car camping.

The Concept:

I decided to design a product or products that would keep your utensils from setting on the surfaces typical to camping, such as the picnic table or the top of your cooler. (The current design is at the bottom of this blog.)

The Design Process:

The first design was a simple, flat product that could be hung up and held cooking utensils, eating utensils, and dish towels. To hold a dishtowel, a slot could be used, but then the moisture from one towel could be transferred to the other, so I instead used a keyhole design, so that the corner of the towel could be inserted into the larger end and pinched tightly into the smaller end of the keyhole.

Version 1:

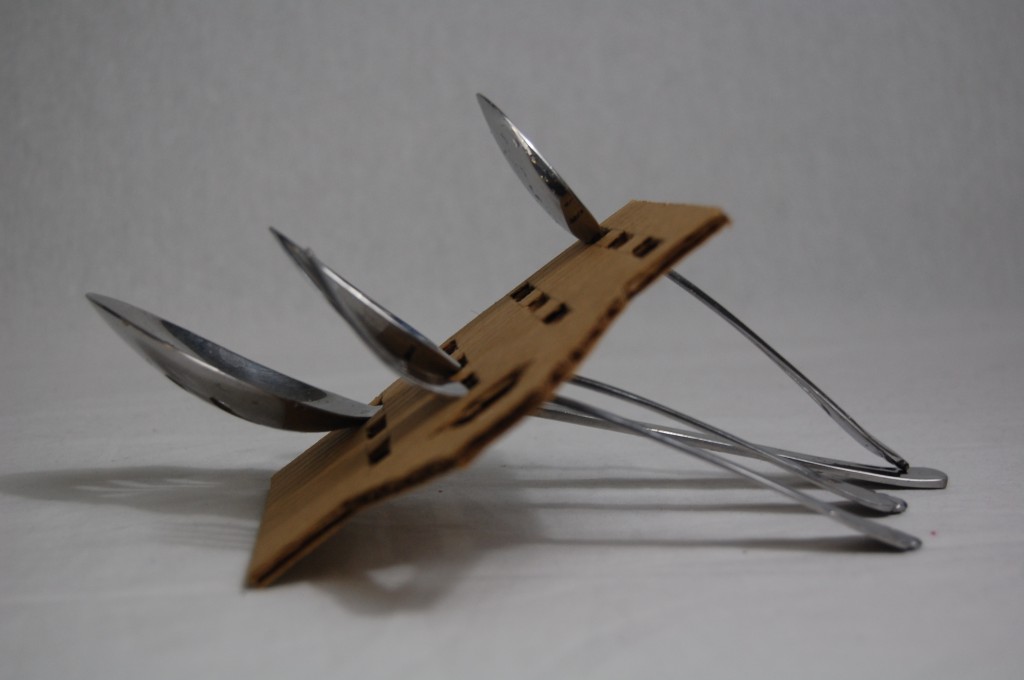

Version 1 Prototype:

The prototype for this version proved to be very crowded when all functions were used, so I went back to the drawing board (in my case, SolidWorks) and began to redesign. To alleviate the issue of crowdedness, I decided to break the product down into three pieces.

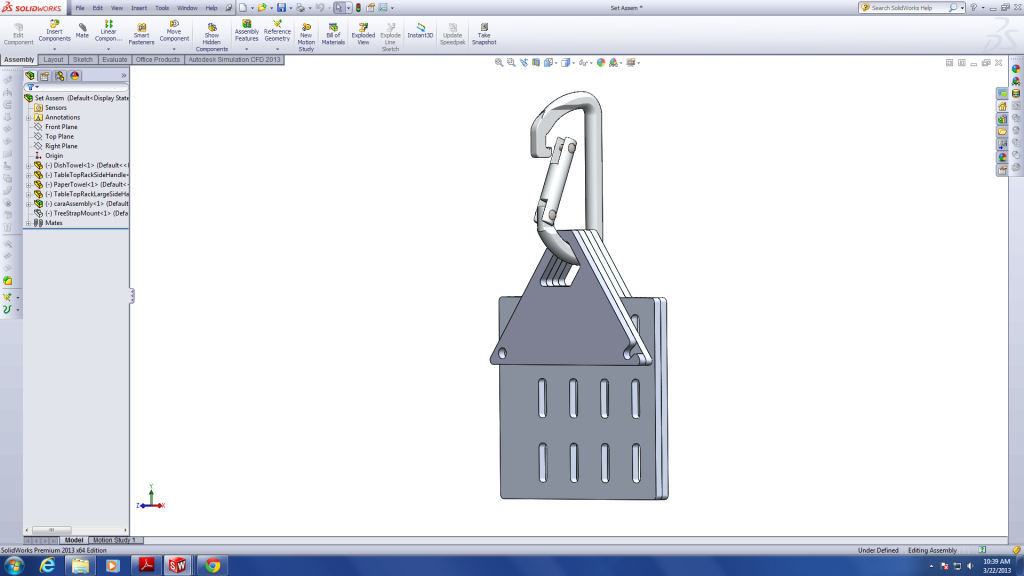

Version 2:

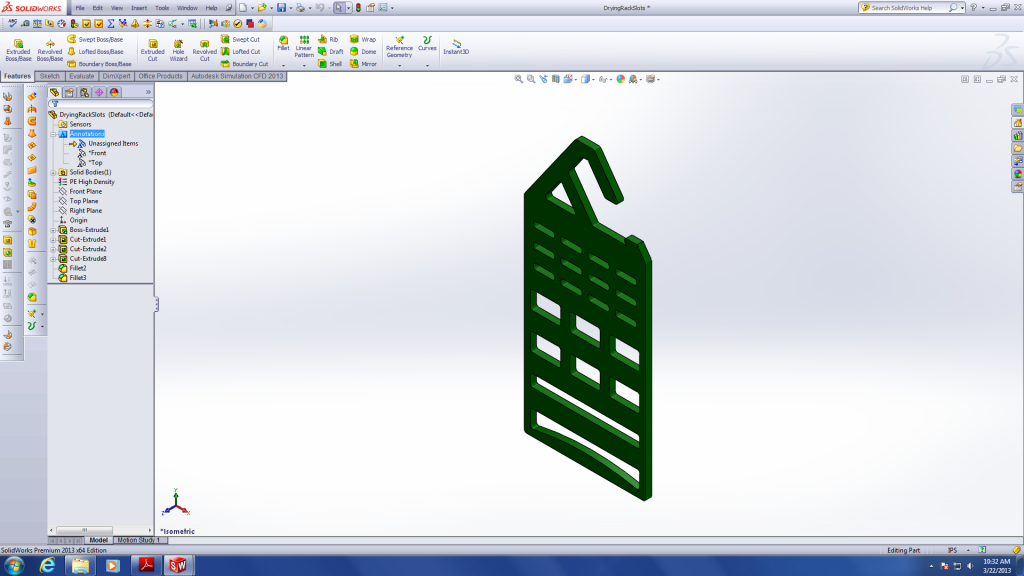

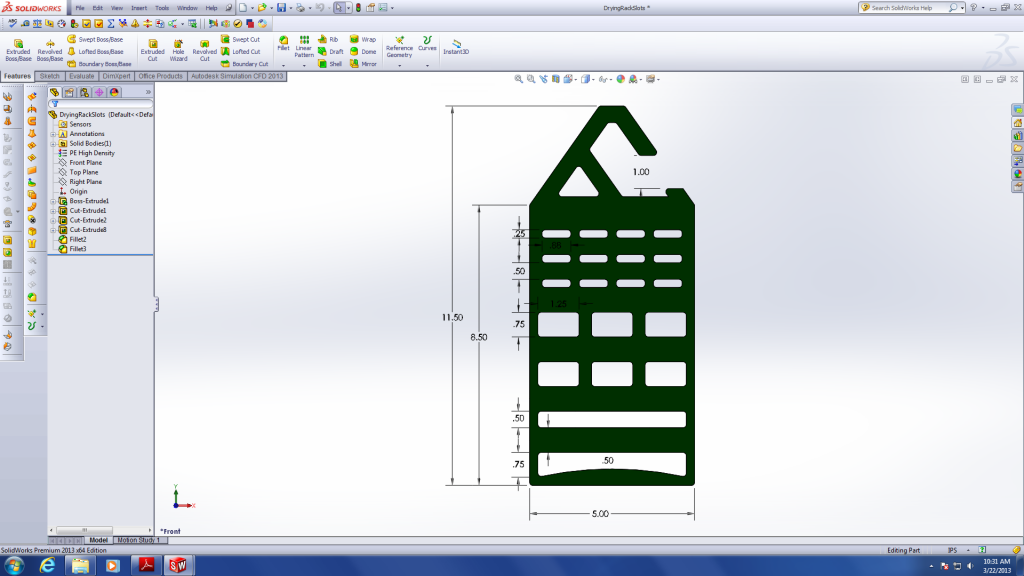

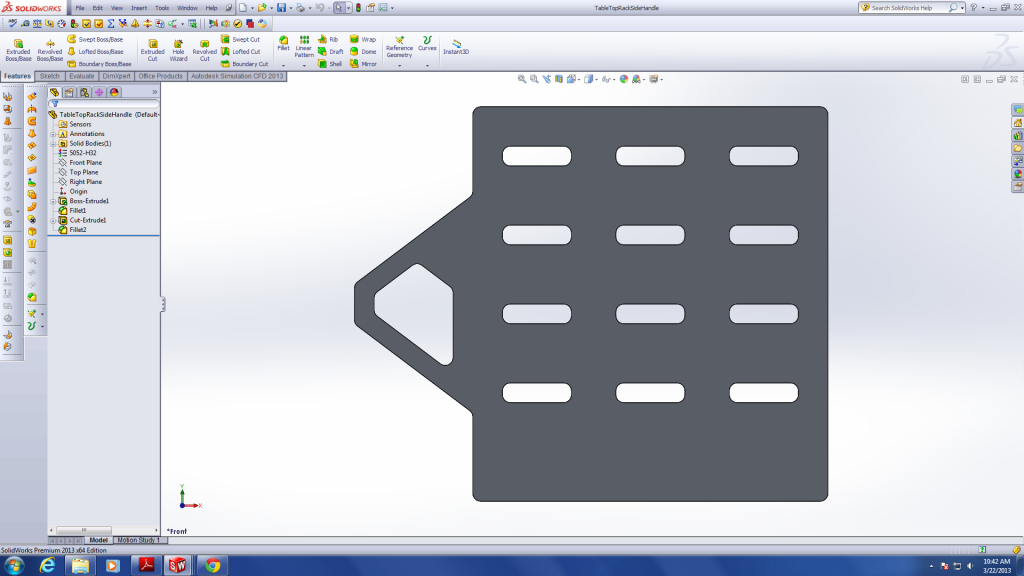

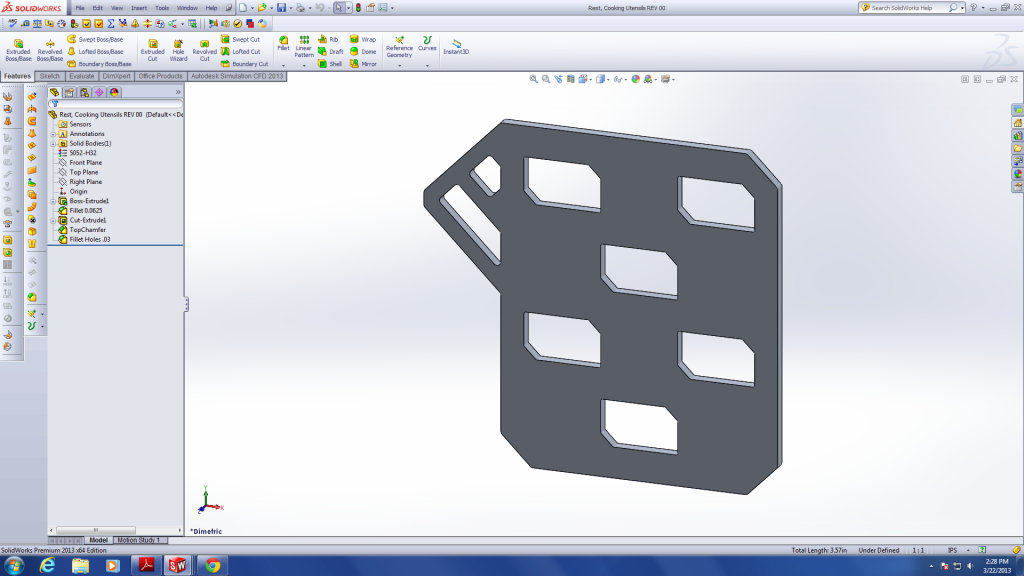

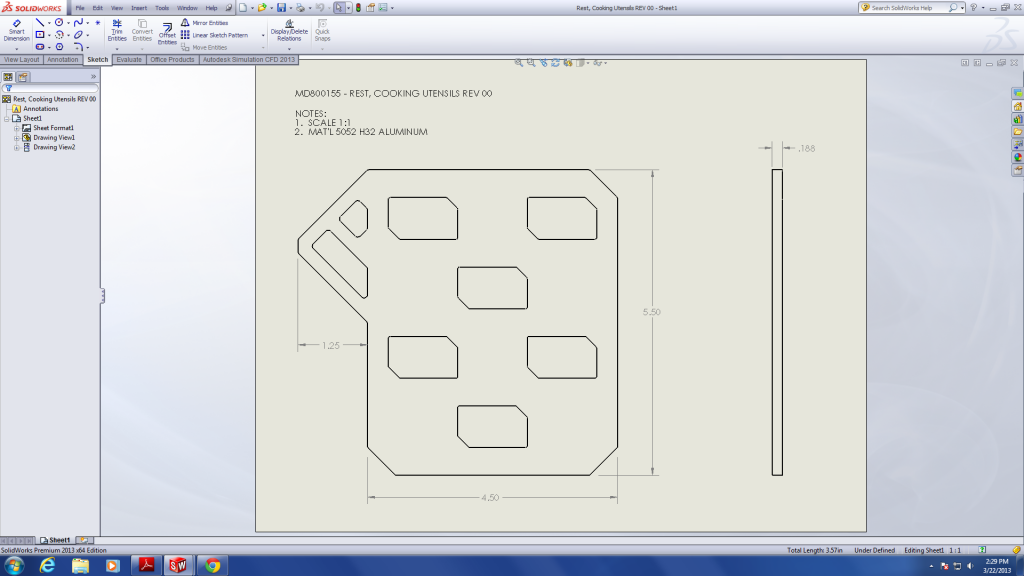

Cooking Utensils Rest:

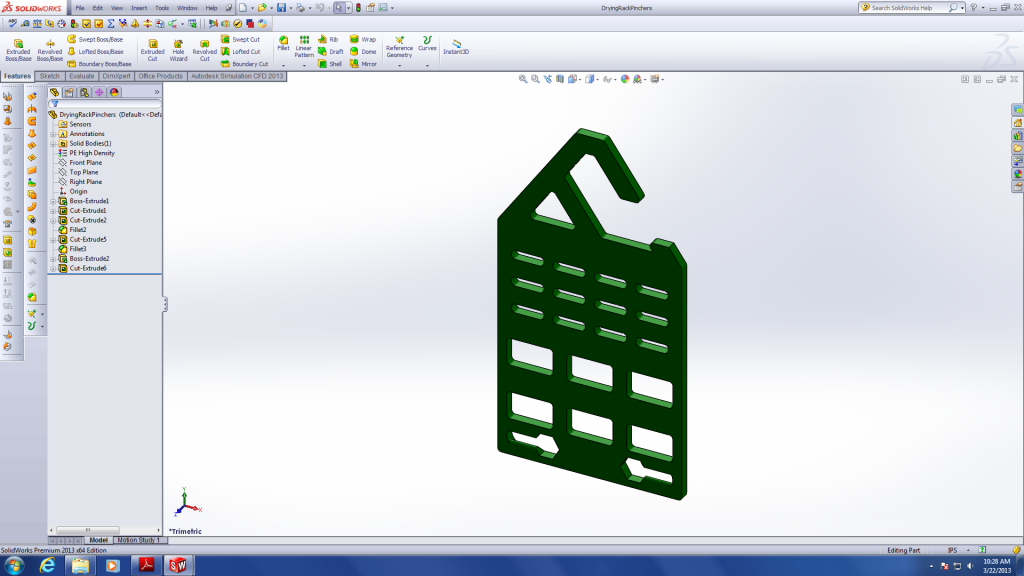

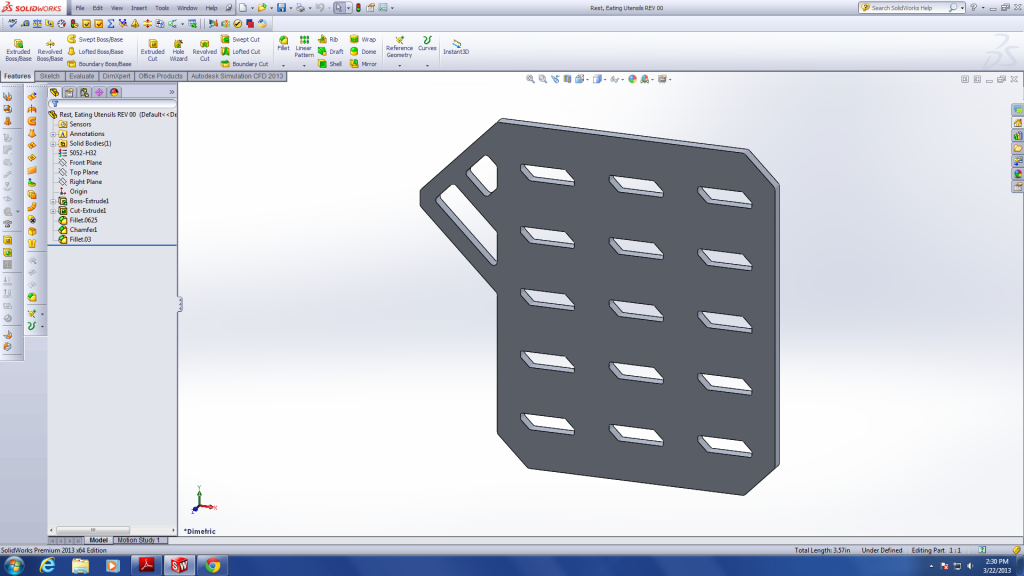

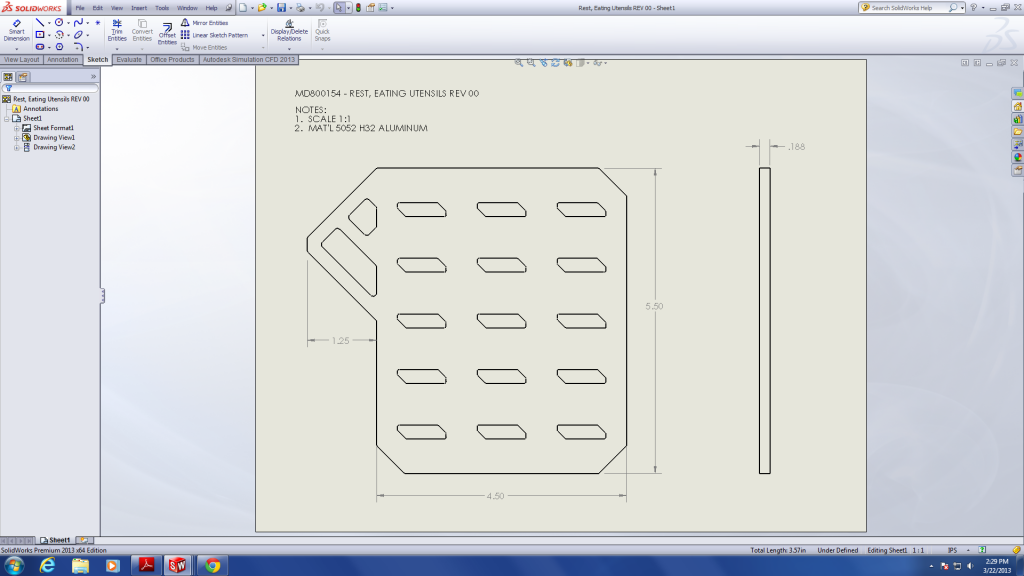

Eating Utensils Rest:

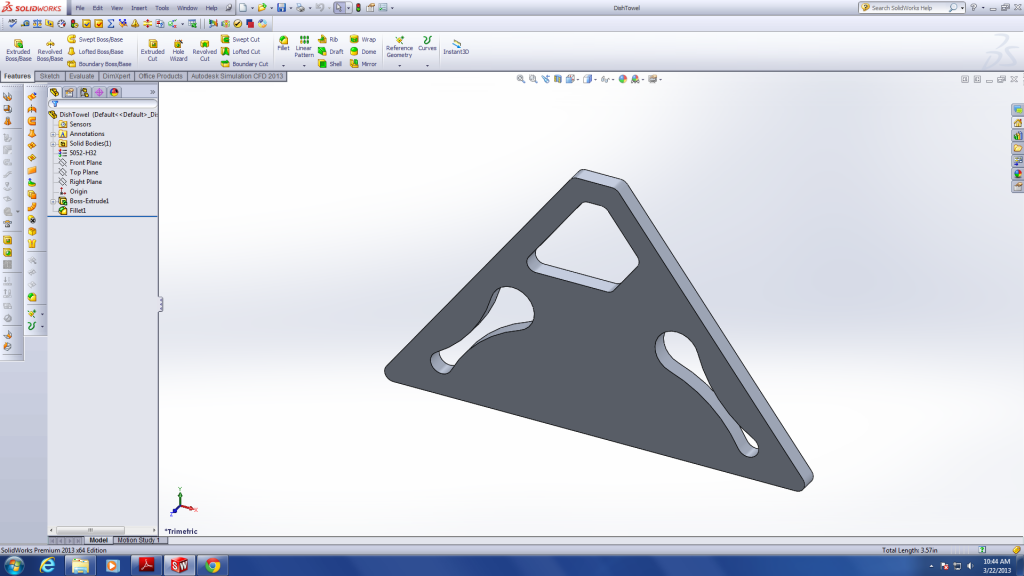

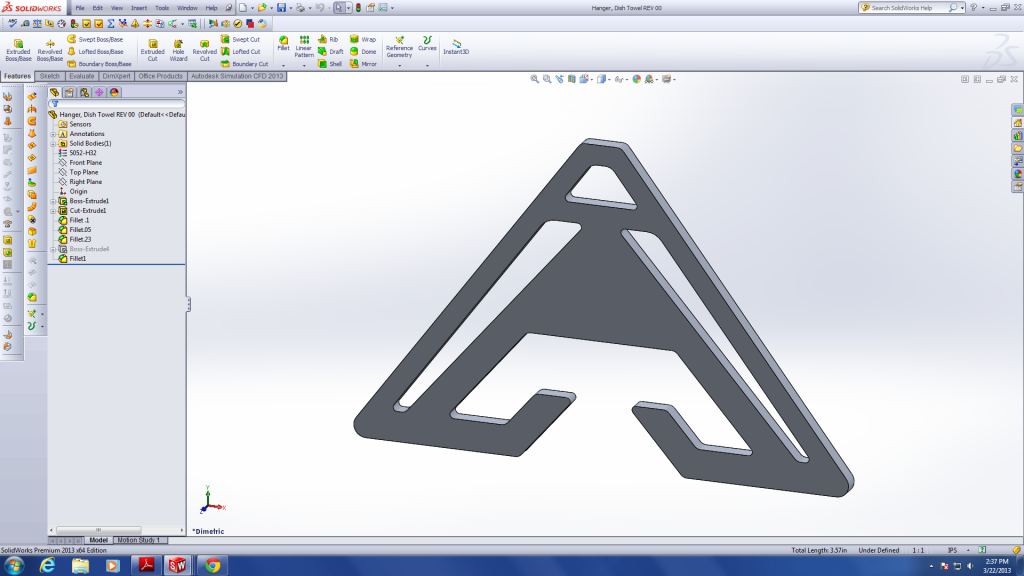

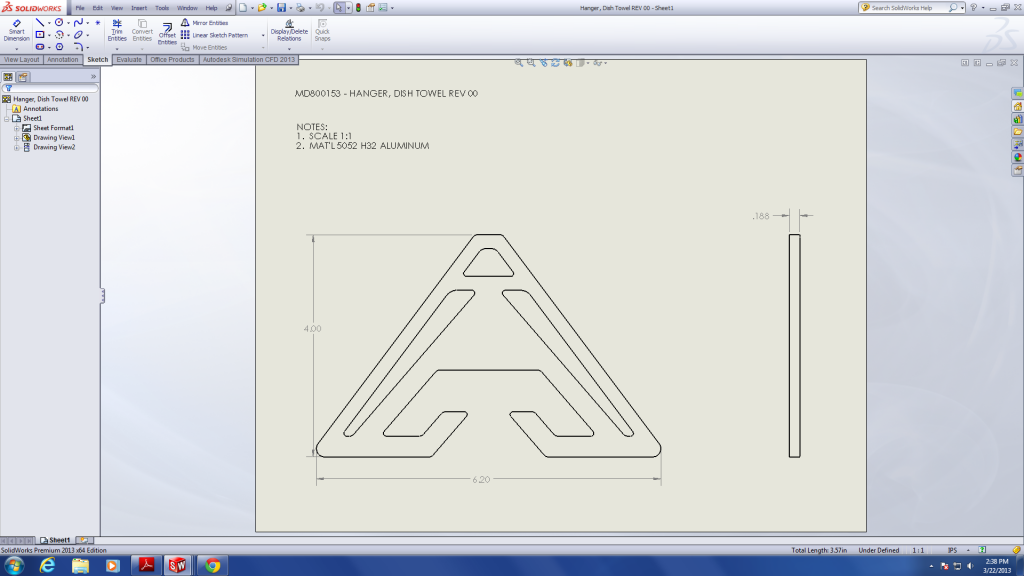

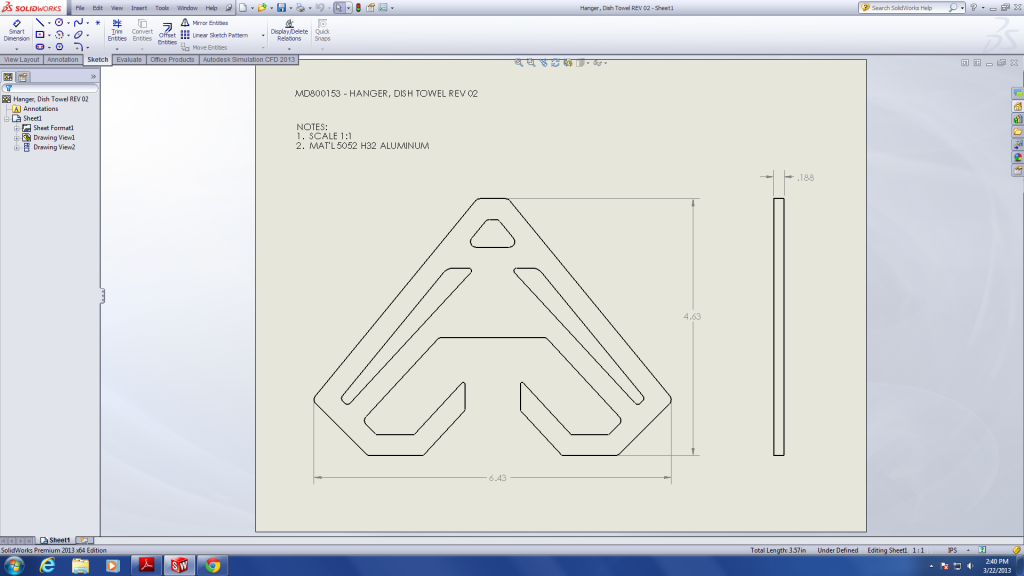

Dish Towel Hanger:

The Cooking and Eating Utensils Rest idea developed into a design that could be used by hanging from a carabiner or at the picnic table like the prototypes show.

Version 2 Prototypes:

Cooking Utensils Rest:

Eating Utensils Rest:

Dish Towel Holder:

During testing these prototypes, I was able to make sure that this design could also hang from a carabiner and still efficiently hold the silverware as well.

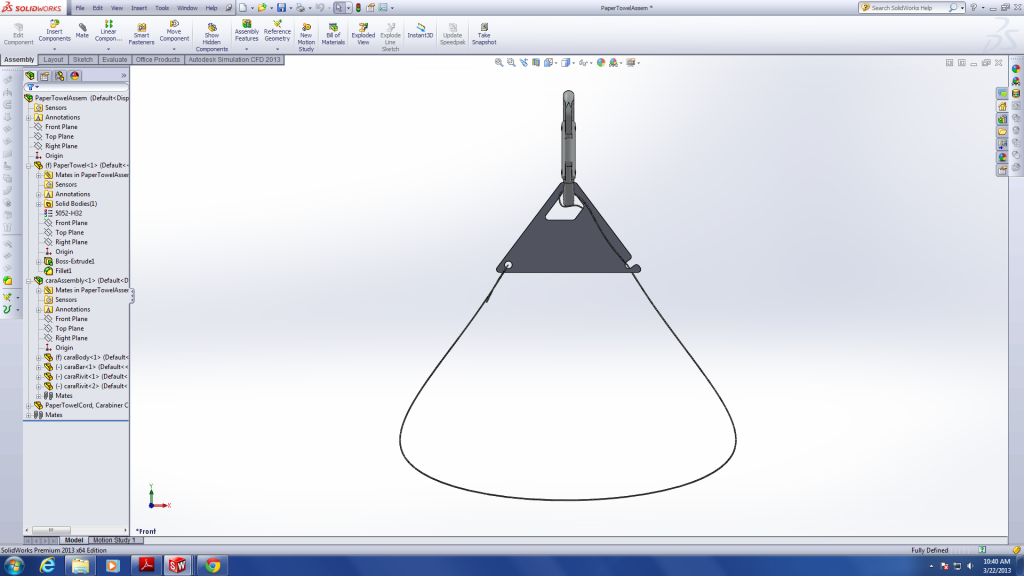

It was during this phase that I also developed an idea for a Paper Towel Holder.

Version 2 Add-On:

Paper Towel Holder:

Using the same shape as the Dish Towel Holder, a wire could be permanently connected at one corner, ran through the paper towel roll, guided through a small notch for stability, and a loop on the end could attach right to the carabiner.

Version 2 Add-On Prototype:

The four items comprised The Clean Kitchen Set, Version 2:

The Current Design:

After consideration, the this specific Paper Towel Holder has been excluded from the set because ideation sessions with Montie yielded a completely different configuration to be pursued at a later date. The Cooking Utensils Rest, the Eating Utensils Rest, and the Dish Towel Holder, however, have continued to develop. The design of the Cooking Utensils Rest and the Eating Utensils Rest are as follows:

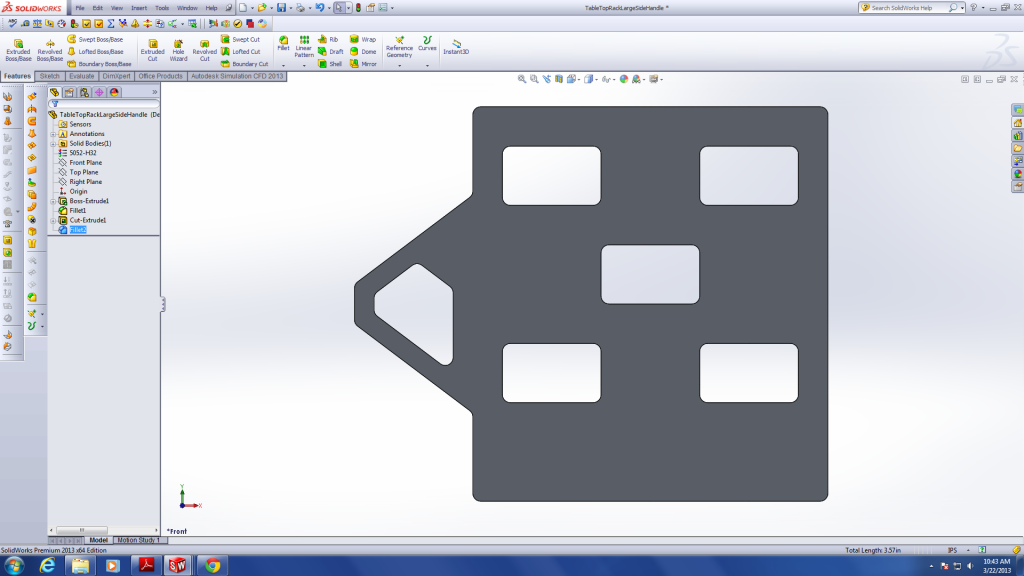

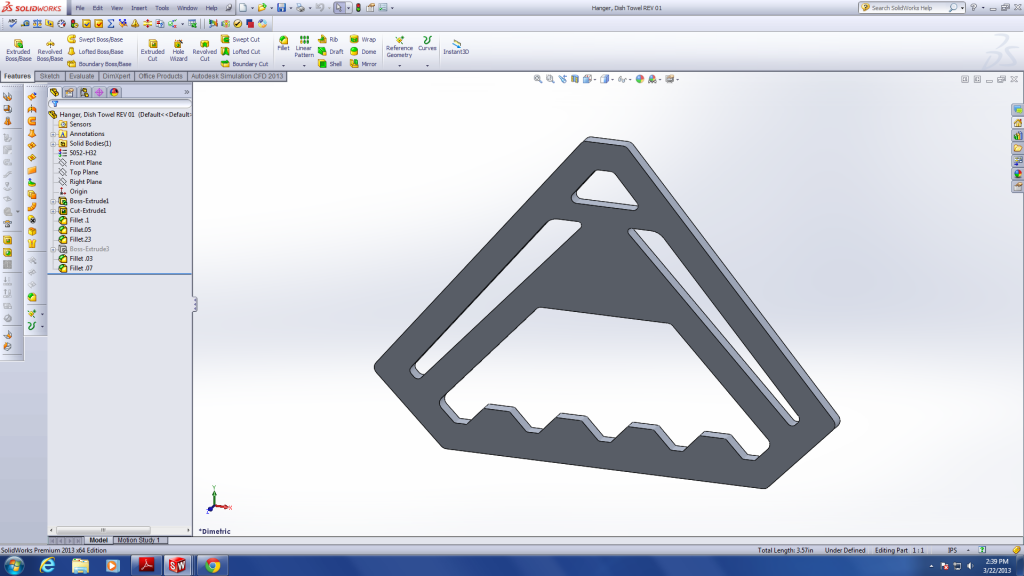

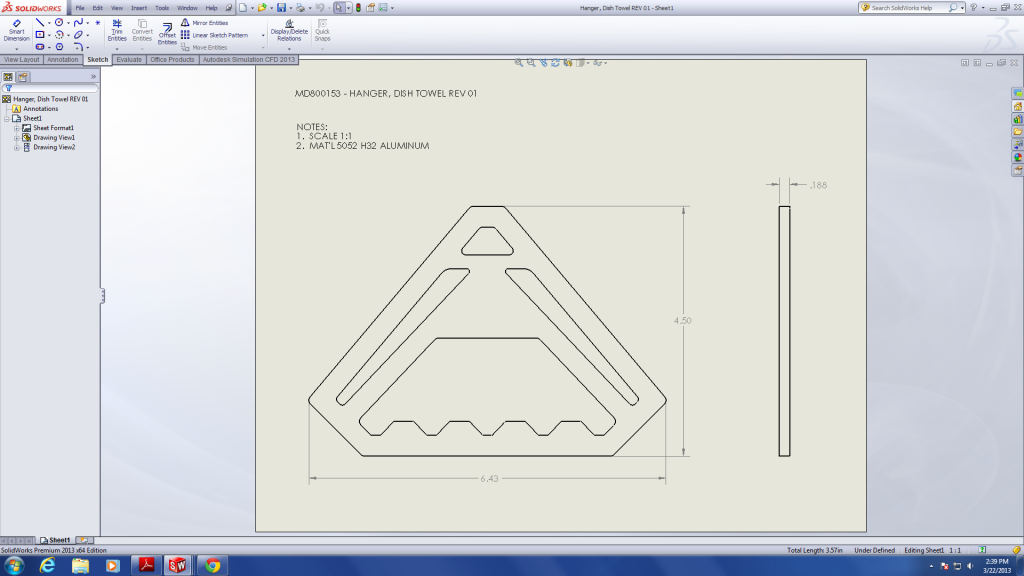

The final design of the Dish Towel Holder has not yet been decided on, but here are the three contenders:

Option A:

Option B:

Option C:

(If you have any suggestions, or preferences, please feel free to leave a comment for me!)

Current Status:

The Cooking Utensils Rest, Eating Utensils Rest, and all three possible versions of the Dish Towel Holder are currently being cut at a water jet cutting facility nearby. We are testing these designs in both aluminum and ABS plastic. I will update soon with pictures of the prototypes when we receive them.

Weekly Podcast: Personalities and Personas

Personalities and Personas is an great tool that helps you sort through all of the options, features and benefits that you are faced with in the early stages of a project. Join me in discussing how to deploy and use this simple, but effective tool.

Montie Design President’s Article Featured in Product Design & Development Blog

Check out Montie Roland’s article on the blog about how to look beyond the design process.

Click Here to view the article on PDNet.

September 2012 Newsletter

Montie Design Completes LED, Environmental Testing, and Tolerance Analysis Projects

Our talented innovation and commercialization team has recently completed several projects showcasing our firm’s diverse portTfolio of product design and technical consulting. Summer 2012 efforts include a complex tolerance analysis study performed for a leading supplier of interconnect products, several different LED lights, and large environmental test chambers. The tolerance analysis study — for a component in a rack mount chassis — was produced on a parallel course as the design of a reference enclosure for our client. As the design team members created concept sketches and models, then 3D CAD models and drawings using SolidWorks design software, they were crafting the detailed tolerance analysis in white paper format to answer the essential questions of “how do I use the component in a real world design?” and “what are the consequences of using that component in a design?”

LED lights are extremely efficient, but most people don’t realize the amount of concentrated heat they generate. Keeping the electronic circuits healthy requires careful thermal controls. Because of the thermal requirements and the production cost sensitivity, LED lights have to be well designed in order to be competitive with existing non-LED lights and function over a very long life. These LED lights are made in low-to-medium quantities but have to compete with products that are made in very, very high quantities. Challenges like this require a focused design effort with an experienced team that works closely with the client to leverage their internal experience.

Montie Design Participates in Morrisville Economic Development Forum

Montie Gear Expands Product Line, Launches Revamped Website

When we originally built the Montie Gear site we were looking to generate a modest amount of interest and website traffic. To our surprise, we soon found this interest to be well beyond our initial expectations. This is a good problem and now we have a great solution with an enhanced web presence and easier to use shopping cart to better handle orders more quickly. If you get a chance, please check out the new website at www.montiegear.com.

Montie Design Joins the Partnership for Defense Innovation

Call or Email Today to Discuss Your Project

Want to talk product development or need help with a project? Don’t hesitate to contact Montie Roland at 919-481-1845×103 or montie@montie.com.-798

August 2012 Newsletter

Modeling and Simulation

for DOD Needed

On July 17, Company President Montie Roland served on an information technology panel discussing modeling and simulation at the North Carolina Advanced Technologies Symposium focusing on the future advanced technology needs of DOD and other federal agencies, hosted by U.S. Senator Richard Burr. Topics and presenters during the panel discussion included Epic Games, RTI International, and other cutting edge software for modeling and simulation, especially as they related to DOD projects and needs. Approximately 400 people attended the greater event at The Friday Center in Chapel Hill.

Montie Design was proud to share our ‘big picture’ mentality when focusing on something specific like modeling and simulation to address changing usability issues, especially in the fluid military and defense space. As generalists, the Montie Design team operates in multiple industries and looks to vacuums in trends, bringing a unique third-party perspective and experience of other industries into consideration of clients’ product concepts. Oftentimes requiring a cross-functional team involving software, electronic/circuit design, firmware, mechanical, industrial design (ID), and PCB layout contributors, these projects necessitate taking a product-to-marketplace approach, as opposed to a technology-only focus.

An expansion of the NCMBC’s Federal IT Symposia in 2010 and 2011, the objective of the Federal Advanced Technologies Symposium is to establish a dialogue between industry, academia and government and form partnerships to address the future needs of the federal government to meet the challenges ahead.

Montie Design Joins PDI

We are proud to announce that Montie Design has joined the Partnership for Defense Innovation (PDI), a tax exempt 501 c(3) organization which promotes economic development in the defense space. The organization, based in Fayetteville, provides a full-service engineering and design facility with a staff compromised of former Special Forces / Special Mission Unit operators, academically trained engineers and technicians offering expertise in Research Development Testing and Evaluation (RDT&E), Integration of emerging Commercial off the Shelf (COTS) and Government off the Shelf (GOTS) technologies with specific application to Command, Control, Computers, Communications, Intelligence, Surveillance and Reconnaissance (C4ISR) Military operations and systems integration.

With the work Montie Design is doing in the product design, defense and technology sectors, a close working relationship with NC PDI is essential to better serving our customers by keeping up with best practices, industry trends and new technologies specific to military needs.

Spring Creek Facility Rolling Along

In our June newsletter, we announced our new rapid manufacturing facility in Spring Creek situated in the beautiful Troublesome Gap area in the mountains of Western North Carolina. Since that time, we have conducted training around producing high-quality bags for our best-selling Montie Gear slingshots, X-Rest, and AR-Rest products and successfully installed equipment such as two upholstery-grade sewing machines. We have received the first sample bags here in Morrisville that were produced in Spring Creek, and are in the process of launching full-scale production in a matter of weeks.

We are excited at the prospects for this urban-rural partnership to help us better accommodate our clients’ fluctuating workload while bringing part-time jobs to this mountain community of very capable, highly trained individuals, effectively bridging the gap between prototypes and full scale production. Let us know how we can put this facility to work for you!

ProductCampRTP A Great Success

In June Montie Design participated in ProductCampRTP, a half-day, fun-filled experience designed to sharpen product development, ideation and design skills at the beautiful Cambria Suites hotel in Morrisville. Thanks to Cambria Suites for their outstanding hospitality to all the participants who participated in three design games running at the same time.

Approximately 50 individuals floated between the different games, thinking about designs in different ways. It was a great way to share skills and knowledge while networking with peers and making new contacts. By actively participating in regional and national industry educational and networking opportunities, Montie Design is happy to provide our insights and experience to help a multitude of product design-related communities achieve excellence.

Call or Email Today to Discuss Your Project

Want to talk product development or need help with a project? Don’t hesitate to contact Montie Roland at 919-481-1845×107 or montie@montie.com.

Internship Progress 2

My summer internship is wrapping up! In this post you can see how we have defined our product vision and how it is starting to come to life. What started off as one product has developed into three separate but interconnected products. They will be the Utility Shelf, Camping Sink, and the Utility Strap. We see these products working great independently, but also coming together to create a center for camping activity. The Utility Shelf acts as the base for bringing the other two products together. We started designing the shelf first and have taken it through the prototype stage and hope to have a final version out soon. The other two products will be developed later as “accessories” to the shelf. We’re excited to see the results, and to hear what people think!

Internship Progress

Luca Harrell here with an update on my summer internship at Montie Design! In this post you can see some of the market research and initial concepts I’ve done to identify common camping needs and define a product direction for this project. While I’ll admit that researching isn’t the most exciting part of design, it has been a very helpful and integral part of the process. From this research, we’ve identified the need for products that offer both stability and portability. Initial concepts began with these two factors in mind. We want this product to feel rock solid while in use but be able to pack away to fit anywhere. Sound like a challenge?

ProductCampRTP This Weekend

Come join me at ProductCampRTP on Saturday, June 16th from 8AM to Noon in Morrisville, NC for a morning designed to sharpen your product development, ideation and design skills! This event is free, but you have to RSVP at http://productcamprtp.eventbrite.com/. For more information visit: http://productcamprtp.org/.

RFID Field Detector by Montie Design

We are proud to announce the release of our second generation RFID troubleshooting tool, called the RFID Field Detector. This simple tool allows a technician to find the extents of a 900MHz RFID field eliminating the guesswork that was needed before. Our core competency is mechanical engineering and industrial design, so I’m very pleased that the Montie Design staff and family of contributors can design a product that meets a complex radio frequency need in a simple and affordable way. Find out more about this new tool at www.rfidfielddetector.com. Download the brochure by clicking here.

Spring Creek Rapid Manufacturing Facility

We are in the process of standing up a rapid manufacturing facility in Spring Creek, NC. This facility makes use of the very capable individuals in western North Carolina while providing low cost services to Montie Design clients and providing jobs to fellow North Carolinians in a very beautiful and remote, but economically depressed area.

Two weeks ago we conducted training on how to build the mighty Montie Gear slingshots. Last weekend we installed the first two pieces of equipment in the facility. These two upholstery-grade sewing machines bring us one step closer to our planned introduction of the cloth bags for the AR-Rest and X-Rest.

This facility is designed to give us the capability of providing rapid manufacturing services to Montie Design clients, cost effectively bridging the gap between prototypes and full scale production. We are using the Montie Gear production as the means of developing the team so they are ready when you need them. Taking a trip to the beautiful Spring Creek area of WNC is definitely easier and a lot more fun than spending 20 hours on the plane just to reach the pacific rim. Hopefully you’ll give our Spring Creek team the opportunity to show you what we can.

Join Us at NCMBC Advanced technologies Symposium

Please join us in our booth at the 2012 NC Advanced Technologies Symposium on July 17th, 2012 in Chapel Hill. I’m proud to serve as a member if one of the expert panels for the event. Register for the event at www.ncmbc.us.

Call or Email Today to Discuss Your Project

Want to talk product development or need help with a project? Don’t hesitate to contact me at 919-481-1845 x 103 or montie@montie.com.

Special Forces Capabilities Exercise at Ft. Bragg

When I got invited to observe the CAPEX event at Ft. Bragg, I was pretty excited. Once the day arrived there was no disappointment. What a great day seeing the tools and techniques that these great soldiers use to keep our country safe!

My Opportunity to Fire an MP-5 in Full Auto

View out of the Back of the CH-47 Chinook Helicopter

2012 Montie Design / Montie Gear Student Design Contest Winners

The results are in! Luca Harrell took first place with his wet/dry storage and sink product. Jake Eck took second with hi comfortable cooking product. Luca has joined us for the summer as an intern and is very busy working out a plan to make his concept a commercial reality. You can see their entries by visiting the Montie Gear site.

Call or Email Today to Discuss Your Project

Want to talk product development or need help with a project? Don’t hesitate to contact me at 919-481-1845 x 107 or at montie@montie.com.

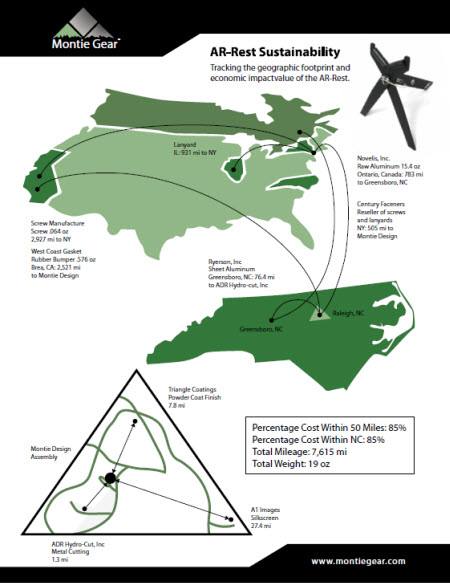

Our First Sustainability / Economic Impact Analysis

I’m personally not a big believer in a lot of the greenwash and pseudo-religious environmental hocus pocus. My family has a tree farm and my dad always taught me that it was my job to leave the forest in better condition than when he passed the management task to me. I think the same philosophy should apply to Montie Design and Montie Gear. To that end, this is our first attempt at looking at the sustainability and economic impact of our Montie Gear products. Click on the image to download the PDF.

Montie Design Student Design Contest – Meet the Contestants

The 2012 Montie Gear Student Design Contest is now in the judging stage. Here are videos about the three finalists.

Click on a picture to watch a video.

Luca Harrell – Industrial Design Major – Virginia Tech

Jake Eck – Industrial Design Major – NCSU

Josh Little – Industrial Design Major – NCSU

Montie Design Networking Event Friday

Join us this Friday, 30 Mar, from 4:00 to 6:30PM for our Final Friday end of the quarter networking event at Montie Design. This is a casual, easy going way to relax a few minutes in the company of fellow professionals. Click Here to pre-register.

Join us at the NC Defense Business Association Expo on April 3-4

Please visit our booth at the Expo in Pinehurst, NC. This event is a great way to find defense related vendors and network within the NC defense business community. Click Here to sign up.

Call or Email Today to Discuss Your Project

Want to talk product development or need help with a project? Don’t hesitate to contact Montie at 919-481-1845×107 or montie@montie.com.