My Journey Into Lean Manufacturing – Kano Model / Don’t Forget Customer Delight

Greetings,

Can you get so Lean (Lean Manufacturing) that you get lost in the process? You bet you can.

Lets talk about the Kano model. The Kano model helps you to organize your product development and management efforts between basic expectations, performance enhancements and delightful additions to your product. Understanding the difference and applying this model to your product management and design management ultimately serves as a reminder to not forget the joy of creating delightful products that please your customers is great ways. Don’t end up getting lost in the process and forget to delight your customers.

Comments and suggestions are always welcome: montie@montie.com.

Cheers,

Montie

How to Design Successful Outdoor Products

Designing any great product is easier when the designer and engineers to have an appreciation for how they are making the customer, reseller and distributor’s life easier and more profitable. This podcast explores how I was motivated to design products for the camping / glamping market. We’ll also explore what it means to have a robust product.

Call me at 800.722.7987 or email montie@montie.com or visit montie.com to discuss how we can help with the design, engineering and prototyping of your next product.

Here is the transcript from the podcast.

Hi, my name is Montie Roland. I’m with Montie Design in Morrisville, North Carolina.

I’d like to spend a few minutes today talking about keys to success in designing an outdoor product.

Let me tell you a little bit about what we do. Montie Design is a product development firm. And we’re also the manufacturers of MontieGear line, which is a line of outdoor and shooting-related products.

I personally enjoy designing products of all kinds. One of the products I enjoy the most is products that are outdoor related. I enjoy spending time in the outdoors – enjoy camping, enjoy backpacking – so I’m always trying to come up with, you know, what’s a way to make that trip more pleasurable, safer, easier. Or what’s a way to extend the capacity and do something better.

I think a lot of us have spent time camping. A lot of times, when we’re growing up, maybe going car camping . . . maybe you just went once or twice. Maybe it was with Indian Princesses or with Boy Scouts or Girl Scouts. But being outdoors, there’s a certain freedom and there’s a certain . . . lack of captivity then you are when you’re between four walls. Now the trade-off is that you got to work a little harder. It’s . . . not as comfortable, sometimes. You’re out of your comfort zone. You don’t have some of the comforts of home. And so . . . equipment over the past few years has changed in some ways; in some ways it’s very similar. When you’re camping, you want to be comfortable. You know, one of the horror stories you see on the commercials and on TV (and maybe experienced) is getting wet. You know . . . my daughters and I were camping in the Shenandoah’s a few years ago, and Hurricane Bob came through. We had no idea which way that hurricane was going to go. And we had planned this grip in advance and we finally said, Hey, let’s just go. And worst case? We’ll just drive home. And so we were up in the Shenandoah’s and . . . it rained. And . . . and then the tropical storm actually passed over. And it rained. And, did I mention it rained? Yeah. And in between the rain, there was rain. So, needless to say it was a challenging environment for about . . . I don’t know – twenty-four hours? When it rained for twenty-four hours. Did I mention the cooking in the rain? Or no . . . yeah.

But, anyway, so our tent wasn’t up to the challenge. Now, thankfully, our Aerobed was. So, late that evening, our tent in one corner had about two foot of water in it. And the average depth in the tent was probably six inches. Now, we were car camping, and thankfully, we had put everything in boxes, these waterproof . . . or, pseudo-waterproof boxes, because we had stuff in the truck. So, we had the bed full of camping gear. And . . . so when it rained and tent flooded, we . . . we were laying on the Aerobed, and the Aerobed was floating. Our boxes were floating. So, if you wanted something out of a box, you had to reach over and grab it, pull you to it, take the lid off without tipping it over and bringing water in. Also had to be real careful not to let your sleeping bag fall off the Aerobed, because if you did, it was wet.

So, it was definitely challenging in that way. I think that we still had a good time. Have to ask my daughters. I might be being optimistic. But . . . so in that case, the product didn’t live up to the challenge. I ended up taking the tent back.

So, when you’re outdoors, one of the things you want to provide with your products is you want to enhance the comfort of the trip, if you can. Now, the product may itself enhance the comfort. So, let’s say you’ve got an inflatable mattress, making sleeping more comfortable. That is so nice when you’re camping. But at the same time, I think it’s important to also think about how the product’s carried, how it’s stored, how it’s used. So, for example, you may enhance the comfort of the trip by making an existing product easier to carry. So, for example, if something’s big and bulky and takes up too much room in the car, or in your pack, then you may find that it’s really uncomfortable. Or, let’s say that for some reason it pokes you in the back in your backpack; when it’s in the backpack, its poking you in the back. Or it’s causing some sort of other transportation dilemma. So, how the product is carried, how it packs, how easy it is to pack – those are all things that can help make your trip more comfortable in that respect. And also, less work. One of the things with our Montie Gear products that we push is to have products that are very, very easy to assemble. Because when you’re tired, it’s raining, its dark, its cold, the last thing you want is to have a product that’s overly complex and difficult to assemble. Because once that happens, those conditions amplify the difficulty of using it, assembling it, breaking camp, what have you. And you’ve lowered the user’s perception of the product, possibly to the point they’re done with it.

So, you always want products that are easy to assemble, easy to use. Just because something’s that easy to assemble on your desk at work, when you’re sitting in a comfortable chair and not hungry, not tired, no rain, seventy-two degrees . . . you may be able to do it on your desk and go, Well, that’s not so bad. But then once you get outside, in the outside environment, looking for twelve pieces that you just dropped onto the ground and now found out that the color they are is perfectly camouflaged – those all add aggravation. So, you want to have products that are low aggravation. And generally, readying the product for use – assembly, what have you – is an area where we’ve seen a lot of . . . I have personally when I was camping seen a need to really think through the product. So, you want a product that’s comfortable; you want a product that easy to assemble, easy to bring to bear, easy to stand up. We want a product that is easy to use. There again, if you’re sitting by the fire and its dark, having some precision alignment of holes before you can put something in a pin, before you can, you know, use it; maybe you have to take it apart between uses and put it back together. Well, if it’s difficult to do in the dark, there again, you may have a product that just doesn’t fit that environment.

So, that . . . that goes to the issue of being robust. Robust products are easy to use, easy to assemble, and hard to damage. And give you . . . also, I will argue that a truly robust product gives you ways that you can use it in ways that the designer never intended. So, maybe there’s a “I intended to do ‘A’”; your customer does “B”. At that point, that’s a really valuable piece of feedback to know because that may open up a whole new market for you. Or, give you an idea of a new product you should design.

So, robust products are ones that they are just easy to use, hard to damage, and easy to assemble, easy to take down, and give you options. Sometimes you can do stuff twelve different ways. Sometimes it’s one, depending on the product.

So, the other thing is you want products that are rugged when you’re designing for the outdoors. Now, sometimes you have limits on that, how rugged they are. A great example is a tent pole. Tent poles, by nature, tend to be fragile to keep weight down, especially with backpacking tents. So there’s this implicating understood trade-off that when I lay out my tent poles from my backpacking tent on the ground, I don’t want anybody around because I don’t want anybody to step on it and bend it or break it. And so I understand that the trade-off of having a four-pound-ten-ounce tent is the fact that the poles are delicate until they’re assembled. Now, they’re easy to assemble with a shock-cord and so forth. But until they get into the tent, they . . . can be hard to . . . can be delicate. Now, once they’re on the tent, they need to be extremely robust. That fifty-mile-an-hour wind, or that six inches of snow, that tent needs to come through that, and that pole needs to do its job with no problems what so ever.

So, there are times when the rugged nature and the robust nature has to be within a specific pattern of use, or a specific part of a pattern of use. And I think the other thing that’s important when you’re camping is that you want a product that looks like it should be a product when you’re camping. Now, one of the things that has changed about this is that for a long time camping products were very functional. They looked like something that you’d buy at the Army Navy Store. A good example is Coleman stove. A white gas later gave way to propane. But, they’re great, they’re rugged; you can fix them with a . . . a knife and a screwdriver, some oil; and they’re just great products – they last forever. And I think long life is usually a by-product of having something that’s rugged and something that’s robust. So, a lot of these cots and other things just look like something the military would use. Now, what happened a few years ago is REI came on the scene, a great outdoor provisioning company. And all of a sudden, camping became more upscale. And so as these stores competed for dollars, one of the ways that they made themselves more distinctive was to provide very high quality, very robust products, and provide them at a higher cost, because higher quality robust, what have you . . . and that also gave the opportunity and the need for more industrial design. Where thinking through the customer experience, the customer experience behind the counter, or in front of the counter; customer experience in the field; what the customer sees on the website; reviews; what have you. So, the world kind of changed and now we have camping products that a lot of times are beautiful as well as tough.

And so, with a camping product, you got to also . . . you know, where does it fall? Is it an inexpensive product? And Coleman is an expert at providing relatively inexpensive, less frills, less performance products. Or, is it a product that is a higher quality product and a higher end product (something you might see at REI)? And then in the past few years, there’s also been a switch to what I’m going to call “Glamping” products. And I think glamping . . . which another way to look at it is called “glamorous camping”. It’s something we can thank the Europeans for. And we were headed there anyway. But, in Europe, you can go camping at a campground and camp in a two thousand square foot tent with flat screen TVs, satellite cable, Persian rugs, couches, that are really, basically, high-end homes made out of fabric. And so the option of doing glamping, I think, is starting to come to the U.S., and that’s going to impact some of the products that are designed for this market as well. So, just to keep that in mind, you’ve kind of got a low-to-midrange, which is the Coleman products; a lot of products that folks who own RVs buy; and then the mid-range . . . mid-low-or-high, which is REI – so you’ve got brands like Patagonia, you know; Merrill. And then you’ve got high end, the glamping products. And that kind of gives you, hopefully, gives you a framework of where to start when you have to look at how you’re going to structure this product. Where does it live? And, also, to evaluate whether or not you’ve got the right product designed. How effective it’ll be in the marketplace.

So, these are some criteria. Just to summarize. You want a product that’s rugged. You want a product that’s robust. You want a product that’s high quality. You want a product that fits the intended market segment, be it the lower end (the Coleman, a lot of the RV products), the mid-range (the REIs and Great Out Door Provision Company-type market); or the glamping market. You want a product that’s easy to use, easy to assemble. You want a product that’s easy to assemble when it’s almost dark and raining and cold. You know, can you assemble this product with gloves? Is this a product where once it’s . . . it’s hard to damage once it’s installed, but is easy to install. So, in camping, it’s a very tough market because it’s so functionally driven and so user experience driven. And then also, too, yeah, always keep in mind is that you’ve got different types of camping. You’ve got car camping. You’ve got glamping. And, of course, car camping being you drive your car to up to where you’re going to camp; you unload everything. So, weight and size isn’t so much of a penalty; comfort’s a high priority. Backpacking – weight is everything. Comfort – eh, not so much so. And ruggedness in backpacking is very important, but you have a more sophisticated user that understands that you don’t want to bend that tent pole when you’re twenty miles from anywhere.

So, keeping all those in mind, I hope you design some great outdoor products. If you have a product that you need . . . maybe you’ve got a concept and need us to design an product and then build a prototype and help you get it into manufacturing, or just some small part of that, give me a call, we’d love to help.

Montie Roland, Montie Design, 1-800-722-7987. Or montie (M-O-N-T-I-E)@montie(M-O-N-T-I-E).com. I hope you have a great day. I hope this podcast was beneficial for you. Montie Roland, signing off.

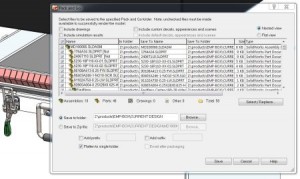

How to Set Up a New Project – Pack and Go’s – Part 2

After many years of setting up projects for our industrial designers and mechanical engineers, here are my thoughts on some basic best practices on how to structure your files and keep your project organized. We’ll concentrate on the importance of Pack-and-Go’s in this segment. This is a very important set of practices that will help keep you out of trouble. These concepts are important even if you have a PLM system, because it helps you understand how the PLM helps keep you organized.

Good morning. My name is Montie Roland. I’m with Montie Design in Morrisville, North Carolina.

And this morning what’d I’d like to talk about is how to structure your project from a file standpoint, from an organizational standpoint.

Montie Design is a full-service design firm in Morrisville, North Carolina. We provide industrial design, mechanical engineering and prototyping capability on-demand to help you move your project from concept to ready-for-the-shipping-dock.

The Concept directories are where you’ll store your sketches, your ideations, maybe your solid model concepts, pictures for your style board. So then, when you think about these files we’re starting to store, you really have two types of files. One type of file is parametric, and the other type of file is static. And then really . . . I guess a third file would be like a . . . a file that’s directly editable. When it comes to Cat files, though, we have two types.

So, parametric files are files that are linked or potentially linked to other files. This is very, very important to keep in mind. So, with Solid Works, we can save a non-parametric file to a format like STEP or DXF or IGES or DWG or PDF. These non-parametric files can be edited, like, easily in the case of DXF or DWG; less easily in the case of PDF. And so these files, though, are generally not going to change just because you changed something somewhere else in the Solid Works model. However, the Solid Works files from Solid Works are parametrically linked in many cases. So, for example, a drawing file is going to go reference the part file to rebuild the drawing. So, if the part file is missing, it can’t reference it and can’t rebuild drawing and get a, basically, a blank screen in the middle of your . . . your drawing. So this is very, very important to keep in mind. Whenever you move files from one directory to the other (and occasionally you need to do this anyway), you run the risk of orphaning a file that’s somewhere else. So a good example of this is . . . let’s say I’m working on (in Solid Works) and I got to McMaster Car and I download a screw (which is a great way to get a screw). So, I download that screw and then I open it up; it comes across as a STEP or an IGES, and then I import it into my model. And when I hit “save” that McMaster Car Screw was saved to my download directory on my local machine. So, if I don’t consciously save that to my Current Design file . . . Current Design directory on the server, then . . . or on the Z-drive, then what’s going to happen is that now I have files in two different places. So, if I was to go and grab Current Design and move it into Release, let’s say. Just copy it over. I would leave that screw behind. Because the copy tool in Windows Explorer does not know about the relationships in Solid Works. So, it doesn’t know to go grab that.

Solid Works has this wonderful utility called “Pack and Go”. Pack and Go finds every file that’s linked to the files that you have open. So, what you want to do is go to the top level of, let’s say, Drawing. Or top-level Assembly. Open up Pack and Go, and then it’ll give you some options. And, generally, you want to exercise all those options in terms of including drawings, including . . . textures, including decals, FEA results; grabbing all that’s good – that way you don’t leave something behind. Solid Works will go look for those files, make a list of them, let you see that list, and then you pick a location where you either want to save that as a zip file, or you want to save that . . . just to that directory; drop the files in that directory. So, you choose that directory and then you hit “Okay”. Then Solid Works will think, and then it will start grabbing files and copying them to that directory. If you do not do this, it will bite you. It is not a question of if it will bite, it’s a question of what moment, what day, and how bad. Because we’ve seen this before. You can imagine that if you have files on a local machine and you just copy them over, or you copy them between places on the Z-drive or what have you, and you orphan some of these files, it can be very painful to find those, get those back. And then you’re never really sure you have the right one. So, let’s say you orphan a single screw. Okay. Worse case, you go download it from McMaster again. But let’s say that you have somehow ended up with a part file that’s in an unknown Rev (or even if we know what the Rev should be) and maybe it’s in some directory. It can very easily happen that you inadvertently saved it to the wrong directory. So, maybe you’re working in Current Design but you’re using a file from Rev 02. But that file is actually Rev 07. So, you grab the stuff out of Current Design, move it to Rev 08. You missed the Rev 07 file. Well, now, all of a sudden, we’ve got no clue where to find that file. And it’s difficult to find without pulling up every single file in . . . on the . . . in the subdirectory on the Z-drive and on your machine, and try to figure out which one it is. And even then, we’ve got to go by the Revision number and properties. And that’s just painful because that still doesn’t tell us it’s the right one. Because there could be, like, a 7 there and an 07 here and which one’s the correct one.

If you do Pack and Go, you avoid soooooo much of that trouble. It’s . . . Pack and Go is your friend. I just . . . this is one of those things that’s important to emphasize.

So, a similar thing applies to other programs. For example, PowerPoint has a Pack and Go feature; use it. Grab all of these images, put them in a Pack and Go file, because that . . . most of the time when you’re working on projects, you end up with images in different subdirectories. It’s on a local machine. It’s on a . . . it’s on your network. But if you do Pack and Go it grabs all those and puts them in the same space. Yes, you use more disk space. I’ll argue that disk space is dirt cheap compared to a few hours of looking for a file you can’t find ten minutes before your deadline.

The same goes for . . . you know, you’re working in an Adobe product. If you have the option to embed it in the file rather than link to it – embed it in the file. I realize this can make your . . . catalog a gigabyte in size. But, it’s so much better than two months’ later pulling it up and missing files. There again, disk space is cheap; time’s not. So, embed those files. Pack and Go. You know, use these features in these programs so that it makes it easier.

Alright, so, it’s also important to note that you have a PLM system, and you do check-ins and check-outs. It’s going to be a little different because that software is going to manage a lot of what we’re talking about. So, I’m not . . . I not sure. I think it’s beyond the scope of this podcast to go in depth on . . . on the PLM systems. But, they’re great. They’re awesome. They help manage some of those. So, in this case, we’re just talking about the manual.

But, on the other hand, if you understand the manual, it makes it a lot easier to understand the PLM.

If you have any questions about this, please don’t hesitate to give me a call. I know it’s kind of a long section here and technical, but happy to entertain your calls, questions. It’s 1-800-722-7987. That’s Montie Roland. Email – montie (M-O-N-T-I-E)@montie(M-O-N-T-I-E).com. Or you can visit our website – www.montie.com. You can see the results of client work we’ve done at the montie.com website. Or you can see some of our projects that we’ve done for ourselves at montiegear (M-O-N-T-I-E-G-E-A-R).com.

I hope this has been beneficial. Montie Roland, signing out.

Podcast: The Corona Effect

Greetings,

The way customers find out about your product has changed. Customer reviews no play a huge role in the success of your products. Join me for a short discussion about this.

This podcast was recorded on a rainy evening while I was camping at a place called Troublesome Gap (elevation 3700 feet) in Western North Carolina. You can even hear the rain during portions of the podcast.

Thanks for listening.

Cheers,

Montie

Podcast: Referrals & Reviews Part 2

Today’s customer, or client, if very well informed. Much of this information comes from reviews on the internet. The effect of internet referrals and reviews on the internet is so important that if you ignore it, your business will quickly suffer. Lets spend a few minutes talking about how this process works and the Montie Gear process for generating great reviews on the internet. This is the same process that took Montie Gear from $0 in sales to a six figure sales performer in 3 years. Click on the play button below to listen.

Please don’t hesitate to email me at montie@montie.com with any comments or if we can help design and roll out your next successful product! Our social review program is a very cost effective way to get the word out about your product.

Cheers,

Montie

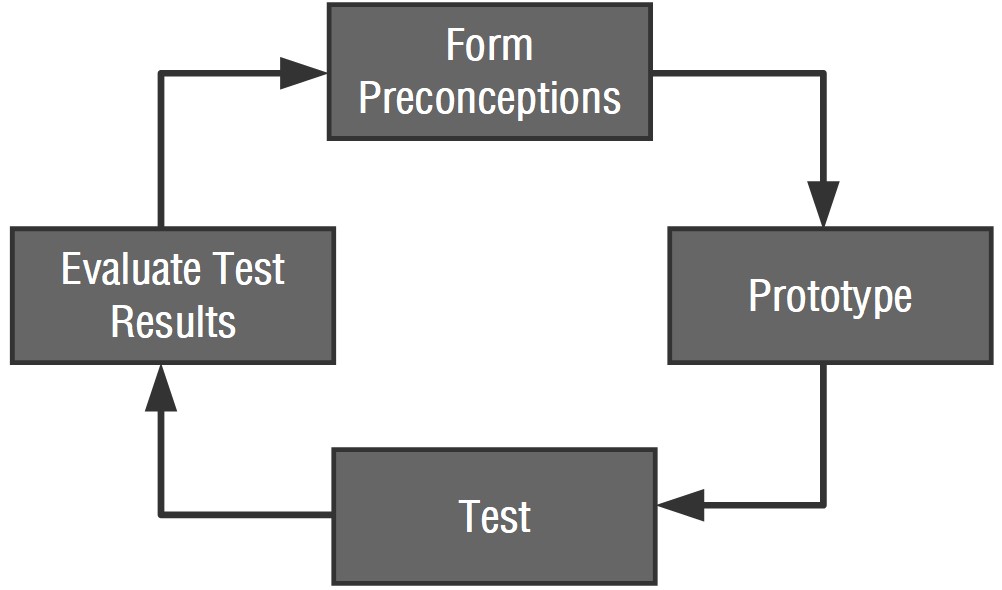

Test, Test, Then Test Again

Product Design 101

Here at Montie Design, we believe it is important to test, test, and retest a design. This process allows us to identify, and modify potential issues in a way unlike traditional sketching or modeling. Michael Laut of Laut Design said it best, “There’s just no simple way to tell what collides, pinches, abrades, stretches, etc without actually feeling what it’s like to use the product yourself.”

We couldn’t agree more. The evaluation stage plays a pivotal role in our ability to produce high quality products for our customers. Shown below is an example of a collaborative project with Laut Design. Here, the shooter’s posture, aim, and balance are paramount. Thus, we are testing a rifle setup on a flat surface to ensure that the preceding points are addressed.

We’d love to hear from you. What is the most important aspect of product design?

Join Us at the 2009 RTP Product Design Street Faire on Saturday, 12 Sept!

The RTP Product Development Guild – a local group of engineers and designers working together to improve the regional economy – is hosting its third annual RTP Product Design Street Faire Saturday, Sept. 12 from 3:00 – 6:30 pm at 400 Dominion Drive in Morrisville. This fun, outdoor networking and educational event will feature exhibits and demonstrations by leading Triangle-area product designers and affiliated professionals showcasing the technological innovation that makes North Carolina a hotbed of state-of-the-art manufacturing design and production talent.

The RTP Product Development Guild – a local group of engineers and designers working together to improve the regional economy – is hosting its third annual RTP Product Design Street Faire Saturday, Sept. 12 from 3:00 – 6:30 pm at 400 Dominion Drive in Morrisville. This fun, outdoor networking and educational event will feature exhibits and demonstrations by leading Triangle-area product designers and affiliated professionals showcasing the technological innovation that makes North Carolina a hotbed of state-of-the-art manufacturing design and production talent.

Admission to the Street Faire is free but requires pre-registration online at RTPStreetFaire.com.

Barbeque, drinks, popcorn, snacks and other treats will be served throughout this family friendly event which will include an inflatable kids’ play area and plenty of shaded space for business networking among peers.

“The Street Faire is a great way for area businesses and manufacturers to get to know product design and prototyping professionals right here in RTP,” Montie Roland, president of the RTP Product Development Guild, said, adding, “Why spend hours on conference calls or travel overseas to work with vendors when you can find the resources you need right down the street? I think people will be surprised at how competitive the region has become in the global marketplace.”

According to Roland, each year has seen increased attendance and vendor participation at the Street Faire, with well over 200 attendees representing a diverse range of business professions and 26 vendors last year. Vendor spaces are still available for this year’s event; pricing and information is available at RTPStreetFaire.com.

Sponsors of the 2009 Product Design Street Faire include Montie Design, the RTP Product Development Guild, Studio Hagler and Trimech, with Gilmore Global as a contributor.

The annual Street Faire is one of many educational and business development programs conducted by the Guild, which also hosts networking meetings, lunch-and-learn seminars, and other events at member locations throughout the year.

“We love our craft and do a lot of different things to promote it, share leads and resources, and build essential working relationships,” Roland said.

For more information visit RTPStreetFaire.com or call 919-481-1845.

About the RTP Product Development Guild

The RTP Product Development Guild seeks to improve the regional economy in Raleigh/Durham/Chapel Hill, N.C. by providing a framework for product developers and startups to work together on products in a collaborative environment. This helps entrepreneurs move products to market that might otherwise languish due to a lack of funding and professional guidance. The Guild accepts applications for products, services or concepts from entrepreneurs, early stage start-ups and corporate spin-offs. More information is available online at www.rtpproductguild.com.

NC Product Design & Prototyping Co-Op Forms

I thought this might interest you. The RTP Product Development Guild is working with local design and prototyping companies to form the NC Product Design & Prototyping Co-Op. Here are a couple of pictures from the event:

Here is the press release:

The RTP Guild Launches New Initiative with Local Companies

Lunch and learn outlines elements of forming product design and prototyping co-op

(Cary, N.C.) The recently launched RTP Product Development Guild – a local group of engineers and designers working together to improve the regional economy – held its first organizational meeting January 29 to discuss the creation of a product design and prototyping co-op.

Eighteen technology-oriented industry professionals gathered for the 90 minute lunch-and-learn presentation and discussion which led to setting co-op organizational goals, objectives, and timelines, in addition to the first membership commitments from local companies.

“Clients sometimes have a hard time identifying local product design resources. On top of that they don’t know exactly who to trust. We want to promote local design talent who have worked together to build economic momentum in conceptualizing RTP as a product design and development hub,” said Montie Roland, president of the RTP Product Development Guild.

In providing a framework for product developers and startups to work together on products in a collaborative environment, Roland said the Guild, through the product design and development co-op, is intended to focus local resources on creating products with regional, national, and international applications instead of having local companies look elsewhere for assistance.

Al Ely of ADR Hydro-Cut, Inc. is a member of the product development community attending the January 29 luncheon who decided to join the co-op. “It is my hope that we can convince customers that we have the talent and facilities here to handle the entire product design and development process from idea to prototype then we can keep as much business as we can here in the Triangle,” he said, adding, “If we can pull it together, we can all keep each other busy with a lot of quality work.”

According to Roland, part of the driving force behind forming the co-op as a group within the RTP Product Development Guild comes from peer professionals like Ely.

“This is shaping up to be a difficult year within the design industry. Working together allows us to reach a broader market space than we could individually,” Roland said, adding, “A parallel to what we’re trying to do is a volunteer fire department, which is contracted with the community to protect the public interest. We are in essence contracting with the RTP business community to improve the regional economy through launching product-driven companies and helping existing companies launch new products.”

The co-op – a part of the Guild – is currently accepting queries from prospective new members and is holding a series of get-to-know each other meetings at area businesses over the next six weeks. For more information contact Montie Roland at (919) 481-1845 or montie@montie.com.

About the RTP Product Development Guild

The RTP Product Development Guild seeks to improve the regional economy in Raleigh/Durham/Chapel Hill, N.C. by providing a framework for product developers and startups to work together on products in a collaborative environment. This helps entrepreneurs move products to market that might otherwise languish due to a lack of funding and professional guidance. The Guild accepts applications for products, services or concepts from entrepreneurs, early stage start-ups and corporate spin-offs. More information is available online at www.rtpproductguild.com.

Bill Seil’s Thoughts on the 2008 RTP Product Design Street Faire

This past September, the folks at Montie Design hosted their annual Product Design Street Fair. It had the flavor of a tradeshow as it brought professionals together in an interactive environment, but by it?s design it was a little different. It offered the same unique advantage any typical street fair or block party would have, giving companies in the area an opportunity to interact on the local level. Newcomers got the chance to meet companies that were right down the street. The folks who returned from previous street fairs, found a chance to stay current with the local product development community and get acquainted with new contacts.

Montie Design works with the attending companies in one way or another, the intent of the street fair is to bring them together in an interactive environment (Download Event Guide / Program or Watch Video). This benefits the design and development community by strengthening communication in a fun and easily accessible way.

Bill Seil

Industrial Designer

info@seil.us

Preview of the 2008 RTP Product Design Street Faire

RTP Product Development Guild?s Second Annual Product Design Street Faire set for Sept. 13

MORRISVILLE, NC ? The RTP Product Development Guild?s second annual RTP Product Design Street Faire will be held Saturday, Sept. 13, 2008 from 3 p.m. until 6:30 p.m. The faire will be held outside of the Guild?s office, which is located off of Aviation Parkway at 400 Dominion Drive in Morrisville, N.C.

?Our street faire is intended to build a stronger product design community by providing a relaxed, family-friendly environment in which vendors, clients and potential clients can get to know each other,? says Montie Roland, president of the RTP Product Development Guild. ?In addition, the event allows attendees to celebrate the product design and manufacturing profession in the Research Triangle region.?

?Last year?s event saw 140 attendees and 16 exhibitors come out,? Roland added. ?We hope to build on last year?s success by increasing both vendor participation and the number of attendees at this year?s event.? We currently have 26 vendors showing off a wide variety of products and services.

There is no cost to attend the event, but pre-registration is required. You can pre-register for the event at: http://productdesignguild.eventbrite.com.

In addition to the RTP Product Development Guild, the 2008 RTP Product Design Street Faire is being sponsored by Montie Design, 101Machine, Trimech, Torque Transmission and Incodema .

The RTP Product Development Guild is a private, for-profit corporation located in Morrisville, N.C. The Guild?s mission is to improve the regional economy by providing a structured environment for product developers and vendors to work together on products in a collaborative environment. This type of open collaboration helps entrepreneurs, early-stage start-ups and corporate spin offs get products to market that might otherwise languish due to a lack of funding or professional guidance. Guild membership and project submission information is available at: www.rtpproductguild.com.

RTP Guild Proclaims October as RTP Product Development Month

by Tom Vass, Vice-President, RTP Product Development Guild

The RTP regional economy has a unique set of economic strengths in technology innovation. The basic platform for all the strengths comes from the population of scientists and engineers who live in the region. Raleigh tops America for PhDs per capita for a metro city.

The RTP is geographically the largest research park in the world and is home to more than 130 R&D companies, employing nearly 40,000 workers. The RTP is home to IBM, GSK, Cisco Systems, DuPont and Sony Ericsson.

The high number of PhDs, and the location of large high tech corporations sets the stage for technology commercialization in distinct product areas. Our focus at the Guild is on product development because that leads to new venture creation which leads to new markets.

New markets are essential for wealth creation because persistence in the status quo distribution from current markets of wealth tends to lead to economic stasis. We suspect there is a mutually reinforcing relationship between wealth creation and new product creation, meaning that the more of one leads to the more of the other.

However, this relationship is perfectly symmetrical, which means that the longer the status quo of current markets remains constant the longer the existing distribution of wealth will stay the same. The result will be lower rates of innovation and new product development.

New products do not get created without a lot of effort, and our basic business model addresses how to help entrepreneurs commercialize their ideas. Our approach to new product development is different than the existing players in the region.

We focus attention on independent entrepreneurs who are not affiliated with the tech transfer programs at the local universities. We also target small engineering and manufacturing firms, and spin-offs from the R&D efforts of the larger corporations. We suspect that many of the 40,000 workers in the RTP have great ideas that could turn into great products if they follow the business development model of the RTP Product Development Guild.

During the month of October, we are going to target product development in the 4 areas we think will be most beneficial to regional economic growth. Each product area shares a common technological platform in both design and production, even though the end market users of the products are different.

On each Wednesday evening of October, we will host an educational seminar at our facilities in Morrisville, N. C., to introduce our model to budding entrepreneurs in each product area.

Our selection of product areas are:

1. October 10. Consumer technology products for the mass retail market.

2. October 17. Health monitoring and home health care products.

3. October 24. Sports and recreational equipment.

4. October 31. Homeland defense products.

We will charge a small admission fee, and our seating is limited to the first 20 entrepreneurs who register to attend. We are soliciting the participation of individuals and small companies who are curious about our business model of advice for commercializing technology.

We think that participants will gain benefits from meeting each other, and listening to how others are going about the process of commercializing their product ideas. If the RTP Guild model seems attractive, then the next step would be to apply as a project candidate for one of the Guilds product development teams.

While commercializing technology is a great objective, we think that the bigger goal for each entrepreneur is to win the Guilds prestigious annual award for the RTPs Most Disruptive Product Technology, presented in March of each year. But, you cant win the prize unless you get in the game.

Registration for the October events is at: www.rtpproductguild.com