We (the interns) went on a field trip this monday, to ADR Hydro-Cut. They do water jetting, and while we were there they cut out sheet metal parts according to our drawings.

The parts arrived yesterday, so we grinded the tangs of and threw them in the washer for a couple of hours to smoothen out some sharp edges, and then they were pretty much ready to go.

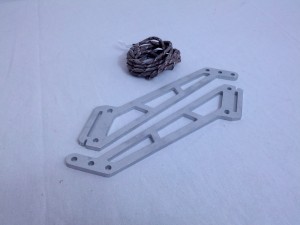

Spent a couple minutes putting it together, and it looks and feels great! I might make some minor adjustments to the drawings, adjusting the angle of the paracord braiding, and I also have to figure out how the braiding itself is done in the best possible way.

Apart from that though, they’ll be ready for anodizing/powdercoating. And with that, we’ll have a product!

/ Robin