My wife and I have this love / hate relationship dynamic with horseradish. We only eat a small amount of it, but we have several family members and friends that really like it. We mostly use it in Connie’s homemade cocktail sauce or on roast beef. Here is a chart showing the pros/cons with horseradish. This should help you decide if you want to grow it. My suggestion is to give it a try, just grow it in an area where you can mow around it to keep it contained where you want it. It will outgrow many garden plants, including asparagus – sorry Connie.

One strategy is to have enough plants that you can harvest about every 3 months. That way you can always have fresh horseradish on hand. The spring and summer harvests may not be as strong as the fall harvest but fresh still wins.

| Pros | Cons |

| Easy to Grow | Can be mildly invasive, best to grow it somewhere that you can mow around (easiest way to contain it, in my opinion) |

| Roots did deep in the soil, which is good to breakup soil | It can be invasive, so you need to make sure it doesn’t spread into unwanted parts of the garden |

| Very hardy | If it spreads into an unwanted area that you can’t mow then you have to week that area to control it |

| Deep roots help breakup soils to a depth of 1-2 feet | Have to dig deeply to remove the roots for processing. Takes time to eliminate from an area because of the roots you miss when digging the plant up to process |

| Tastes great in cocktail sauce or on roast beef. Stores about 3 months (refrigerated). Very easy to grow and you can dig it up any time to make more horseradish sauce | Limited uses. No way to preserve long term after processing (if there is, please let me know) |

| Easy to process | Can be time consuming to peel smaller roots |

| Medicinal uses | None |

| Can be harvested any time in the season | Best if harvested late in the season for best flavor, but not a requirement. Look for yellow leaves, usually after first frost. |

| Limited storage life after processing | Easy to store in the refrigerator |

| Plant pulls minerals from deep soil | None |

| Leaves are mineral laden and make great compost, just leave them where they fall | None |

| Leaves are great supplement for chickens – https://tinyurl.com/2p85yuuz | None |

Processing Horseradish

Step 1 – Wash roots and peel

I washed them outside first (they can be pretty dirty). Then wash them again in the sink. Make sure to remove any dark veins. Use safety glasses and good ventilation to protect your eyes.

Step 2 – Chop the roots up so they fit in the food processor

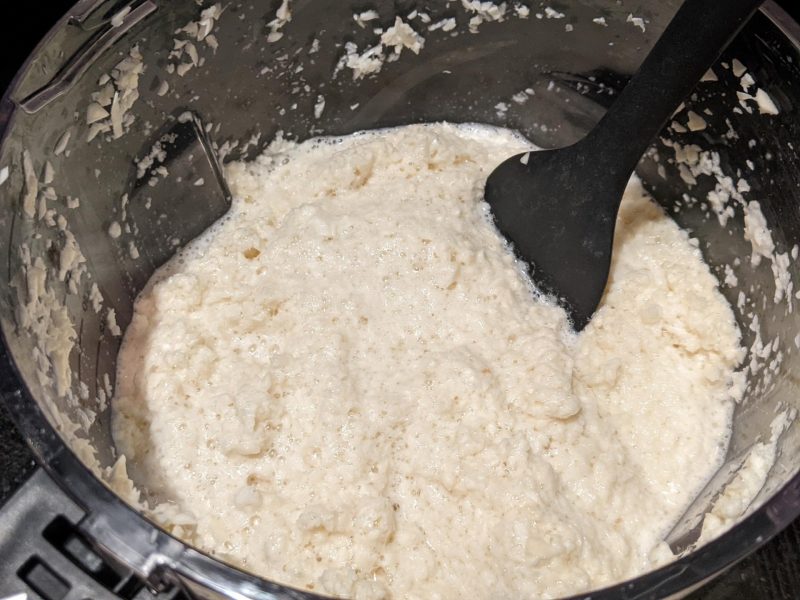

Step 3 – Pulse in food processor until finely chopped but not mushy.

Wait at least 2 minutes before adding the vinegar. The longer you wait the hotter the horseradish will get.

Step 4 – Take one lb of horseradish and add 1/2 cup of white vinegar and 1 cup of cold water. Add approximately 1 teaspoon of kosher salt (adjust to your taste preference

Step 5 – Pour into jars – we use smaller jars because most of the time the amount of horseradish used is fairly small. These are great Christmas presents.

Enjoy!

Note – we’ve had limited success vacuum sealing the jars. I suspect that we would need to do the vacuum sealing process fairly slowly to avoid making a mess.