July – Micromanufacturing In Spring Creek

Audio Transcript

Hi. My name is Montie Roland. And right now I’m coming to you [from] about two hundred vertical feet above Troublesome Gap [at an elevation of approximately 3900 feet].

Troublesome Gap is between the communities of Spring Creek and Big Pond, which is just south of Hot Springs, North Carolina, which is where the Appalachian Trail goes through Hot Springs, and just north of Asheville. And so I had an opportunity to come up this weekend and just relax.

We had a meeting in Spring Creek earlier and a meeting the night before at ASU for the IDSA Student Merit Competition judging. And I was right here, and I said, You know, it might be a good weekend to pitch a tent and sit back and just relax. So, that’s what I’m doing. So, right now, I am literally the only person within three-quarters of a mile of where I am. I think the closest people, from right here, from where I am, are Bob and Patsy Allan, who are down farther on Baltimore Branch Road. And they’re about three-quarters of a mile away. So, it’s nice and remote up here. And then the next neighbors . . . there’s another neighbor about three-quarters of a mile away and then you got to go farther to get to more neighbors. So it’s quiet up here. It’s about to rain, I think. It’s been holding off all day but . . . so I built a fire, pitched a tent, and there’s a stack of wood in kind of a U-shape behind the fire, which keeps the wind off. There’s a lot of wind up here. And it comes from Tennessee and comes up the Spring Creek Valley and it’s pretty energetic. So we have to build this pseudo-kiva structure to keep the wind off the fire. And I’ll tell you that has a really nice effect of pushing a lot of that heat back, I believe. Or maybe it captures it and radiates it, but, whatever, it’s nice and cozy warm here. It was in the high-70’s today and now it’s a little cooler.

So, it’s nice to get away. It’s nice to sit back and relax and enjoy life.

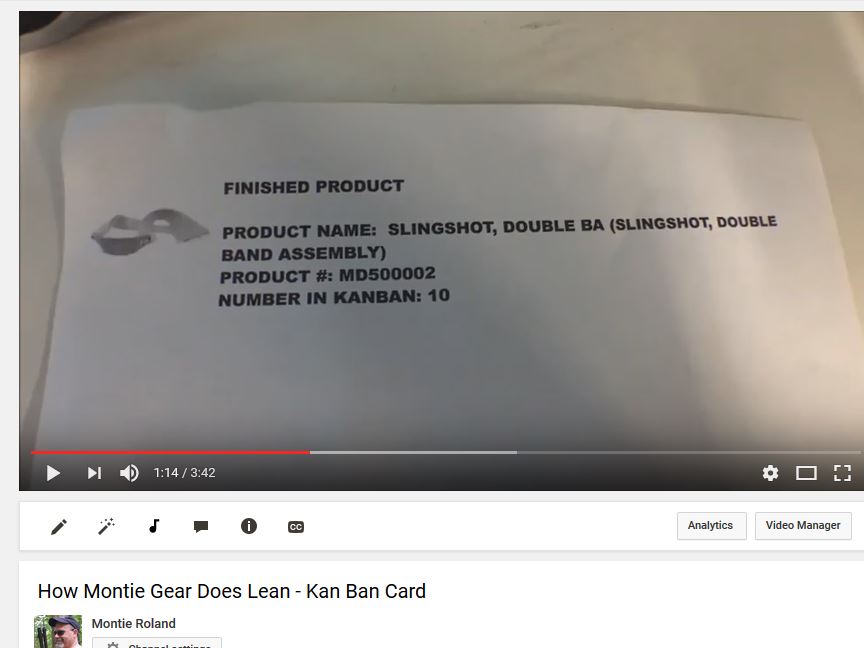

So, we are, as a company, Montie Design and manufacturers of Montie Gear products, are setting (or in the process of) setting up . . . I’m going to call it micro-manufacturing facility for now. Maybe one day we can actually graduate to the mini-manufacturing facility size. But we’re planning on renting a building up here and down in the valley in Spring Creek, and have a couple of local folks that work part time and do some assembly for us. And hopefully grow that into a way to bring jobs to this community. And then also serve our Montie Gear clients better, and our Montie Design clients. And I think I just hear my iPhone beep. Boy, that kills the woodsy mood. Sorry about that. But anyway so we’re putting in this facility and been making arrangements to do that. And what I wanted to do was chat a little bit about my vision for that facility.

My contention is that we can have a facility up here, in this remote location, and bring jobs to a group of people who are struggling to find employment. And that also gives us the labor rate that’s lower than what we can do in Raleigh. And hopefully we can put some of this mountain culture and mountain know-how to use in a way that, like I said, is good for the Montie Gear and Montie Design clients; customers.

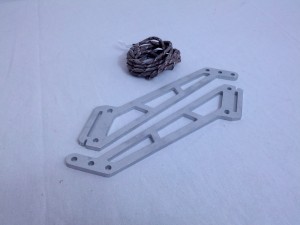

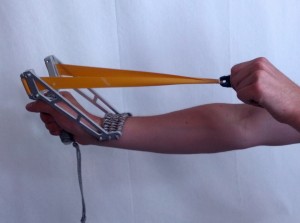

So, what we’re setting up is a very flexible assembly area where we’ll do some of the assembly on our Montie Gear products. For example, the slingshot has a paracord handle, and that’s . . . that has to be woven into the aluminum frame. And it takes . . . its time consuming. So what I want to try with that is to . . . it’s just out to here, so it’s not something we’re doing in the office anymore in Raleigh; it’s something we’re doing up here. And I think that’ll work out as a win-win for everybody. You know, that brings some work here. It keeps our labor rate low, which is a win for our customers, too, because that helps our prices reasonable.

So, as a Montie Design client, you know, what’s the benefit for you if you’re a Montie Design client? And that is, now, we have a good way to do that initial prototyping for you, where there is a . . . you’ve not moved it to a full-blown contract manufacturer, but maybe you want to get the first hundred units out while you’re tooling up or what have you. And so I think this is a lot more cost effective way where we can take that product (a lot of times one we designed), shift it over to here to be assembled, tested, debugged. And so that way we’ve got this very flexible facility – very small but very flexible – taking your product and building your prototypes. And I’m thinking this is the . . . you know, we’ll build the first few prototypes in the office, develop some documentation, and then we move those prototypes to here and maybe that’s the first two hundred . . . thousand, what have you. But you get those fairly quickly; we can use to make those . . . maybe they’re cast parts; maybe they’re rapid prototype-type parts, but . . . what have you. So those first market samples go out.

So that’s kind of part of the reason . . . big chunk of the reason we’re doing that is to give us capabilities that we didn’t have before. And a way of keeping that economical.

It’s really beautiful up here; it’s gorgeous. And it’s remote. And, I think the nice thing is that for . . . if your production is up here, you can go meet the people that are building your product. You can see where it’s built; you can see, you know, is this a sustainable model, are we treating people well. And just ask them. And so I think that’s an awfully nice thing in today’s times where we’ve . . . you know, there’s so much, so many times, that it comes over from a boat, and, what was it like when it was made? You know what? What considerations are there for, you know what, how people are treated? Or, you know, how . . . are people paying attention to the quality of your product as they’re putting it together. And so what we’re trying to do here is give you a way to address those concerns. Do it locally and do it in a very cost effective manner.

So I hope as this project progresses you’ll keep track and I will . . . will definitely post information as it proceeds. And that can . . . inspire you to think about, you know, letting us do some of your production here in Spring Creek, North Carolina.

I hope you have a great evening. And I think it’s starting to rain so I believe I’m going to move underneath the picnic shelter to keep me dry.

Thanks. Have a great evening. Bye.

END AUDIO